Table of Contents

Understanding the Importance of Casing Tubes in Pipeline Construction

General Pipeline FAQs | Casing Tube – Department of Transportation

Understanding the Importance of Casing Tubes in Pipeline Construction

When it comes to the intricate network of pipelines that crisscross our landscapes, ensuring their integrity and Safety is paramount. Casing tubes play a crucial role in this endeavor, serving as protective barriers around pipelines, safeguarding them against external forces and environmental factors. In this article, we delve into some frequently asked questions regarding casing tubes and their significance in pipeline construction.

What is the purpose of casing tubes in pipeline construction?

Casing tubes serve multiple purposes in pipeline construction. Primarily, they provide structural support to the pipeline, preventing it from buckling or collapsing under the weight of the surrounding soil or external pressure. Additionally, casing tubes act as a protective barrier, shielding the pipeline from corrosion, abrasion, and other forms of damage caused by soil movement, groundwater, or external elements.

How are casing tubes installed?

Casing tubes are typically installed using various methods depending on the terrain, soil conditions, and depth of the pipeline. In some cases, horizontal directional drilling (HDD) is employed to create a tunnel underground, through which the casing tube is inserted. Alternatively, traditional methods such as open-cut trenching or auger boring may be utilized, especially in less challenging terrains. Once the casing tube is in place, the pipeline is then installed inside it, providing an additional layer of protection.

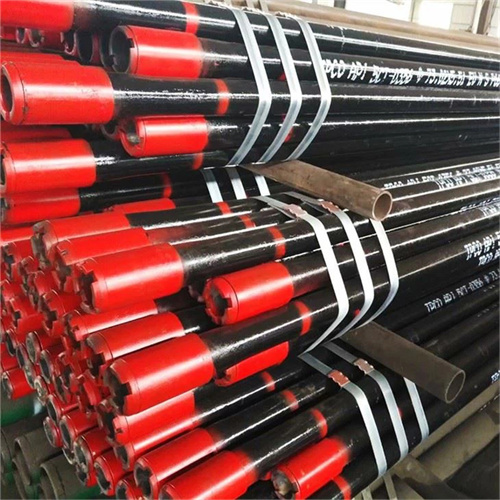

What materials are casing tubes made of?

Casing tubes are commonly made of steel, concrete, or plastic materials, depending on the specific requirements of the project. Steel casing tubes are preferred for their strength, durability, and resistance to corrosion, making them suitable for a wide range of applications. Concrete casing tubes offer excellent structural integrity and are often used in areas where additional support is needed. Plastic casing tubes, such as high-density polyethylene (HDPE), are lightweight and flexible, making them easier to transport and install in challenging terrains.

How do casing tubes protect pipelines from environmental factors?

Casing tubes serve as a barrier between the pipeline and the surrounding Environment, shielding it from various external factors that could cause damage or degradation over time. For instance, casing tubes protect pipelines from corrosion by preventing direct contact with corrosive soil or groundwater. They also safeguard pipelines from mechanical damage caused by soil movement, seismic activity, or external forces such as heavy machinery or vehicular traffic.

What are the maintenance requirements for casing tubes?

Like any other component of a pipeline system, casing tubes require regular inspection and maintenance to ensure their continued effectiveness. Routine inspections should be conducted to check for signs of corrosion, damage, or deterioration, and any issues should be addressed promptly to prevent further damage to the pipeline. Additionally, vegetation control around the casing tubes is essential to prevent roots from penetrating the protective barrier and compromising its integrity.

In conclusion, casing tubes play a vital role in the construction and protection of pipelines, providing structural support and safeguarding them from external forces and environmental factors. By understanding the importance of casing tubes and implementing proper installation and maintenance practices, we can ensure the integrity and longevity of our pipeline infrastructure for years to come.