Table of Contents

Exploring the Production Process of Women’s Cardigans in China’s Processing Plants

The production of women’s cardigans in China’s processing plants is a fascinating process that combines traditional craftsmanship with modern technology. This intricate process involves several stages, each of which contributes to the creation of high-quality, stylish cardigans that are loved by women worldwide.

The journey of a cardigan begins with the selection of raw materials. The most commonly used materials are wool, cotton, and synthetic fibers. Wool is favored for its warmth and durability, while cotton is chosen for its breathability and comfort. Synthetic fibers, on the other hand, are used to add specific characteristics such as elasticity or resistance to shrinkage. The choice of material depends on the desired characteristics of the final product, including its texture, weight, and warmth.

Once the raw materials are selected, they are cleaned and processed to remove any impurities. This is a crucial step as it ensures the quality and longevity of the final product. The cleaned fibers are then spun into Yarn. This process involves twisting the fibers together to create a long, continuous strand. The thickness of the yarn can be adjusted to create different textures and weights in the final product.

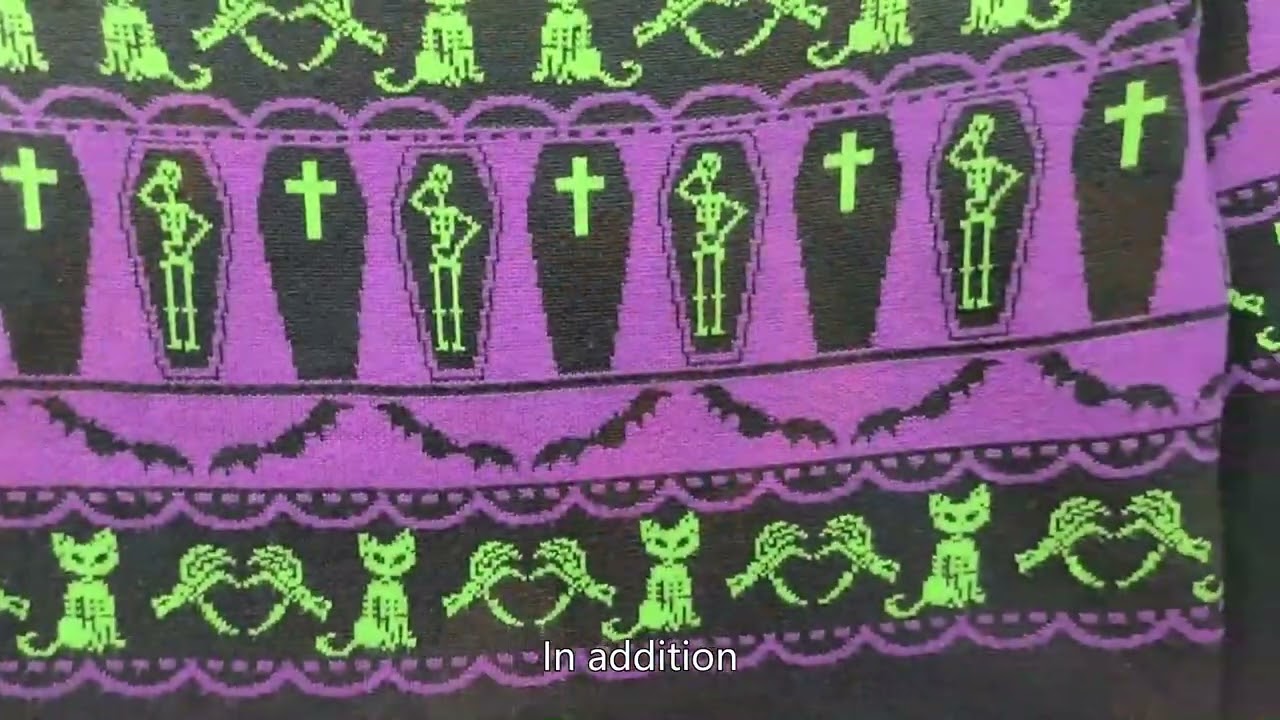

The next stage in the production process is knitting. This is where the yarn is transformed into a Fabric. In China’s processing plants, this is often done using computerized Knitting Machines. These machines can produce a wide variety of stitches and patterns, allowing for a high degree of customization. The knitting process also determines the shape and size of the cardigan.

Once the fabric is knitted, it is then dyed to the desired color. The dyeing process involves immersing the fabric in a solution containing the dye. The fabric is then heated to allow the dye to penetrate the fibers. After dyeing, the fabric is rinsed to remove any excess dye and then dried.

| Serial Number | Products | Fabric name | Supply model |

| 1.1 | knit jumpers | VELVET | Sweater Company |

The dyed fabric is then cut into the various parts of the cardigan, such as the body, Sleeves, and collar. These parts are then sewn together to create the final product. This is a highly skilled task that requires precision and attention to detail. The seams must be strong and neat to ensure the durability of the cardigan.

| Sequence | Product classification | Fabric name | Supply model |

| 1-1 | sweater oem | COMBED | Sweater Company |

The final stage in the production process is finishing. This involves checking the cardigan for any defects and making any necessary adjustments. The cardigan is then pressed to remove any wrinkles and give it a smooth, polished appearance. Finally, any additional details such as Buttons or zippers are added.

The production of women’s cardigans in China’s processing plants is a complex process that requires a combination of skilled craftsmanship and advanced technology. The result is a high-quality, stylish product that meets the needs and preferences of women worldwide. This process is a testament to China’s commitment to quality and innovation in the textile industry.