Table of Contents

Exploring the Production Process of Wool High Neck Sweater in Private Label Manufacturing Facilities

Private label manufacturing has become a significant trend in the fashion industry, with many retailers opting to produce their own branded products. One such product that has gained immense popularity is the wool high neck sweater. This article aims to explore the intricate production process of this fashionable item in private label manufacturing facilities.

The production process of a wool high neck sweater begins with the selection of high-quality wool. The wool is sourced from reputable suppliers who ensure that the raw material is ethically sourced and meets the highest quality standards. The wool is then thoroughly cleaned and processed to remove any impurities, ensuring that the final product is soft, warm, and comfortable to wear.

Once the wool is cleaned and processed, it is spun into Yarn. This process involves twisting the wool fibers together to create a long, continuous strand. The thickness of the yarn can be adjusted depending on the desired thickness of the sweater. The yarn is then dyed in the desired color. The dyeing process is carefully controlled to ensure that the color is evenly distributed throughout the yarn and that the final product will not fade or bleed when washed.

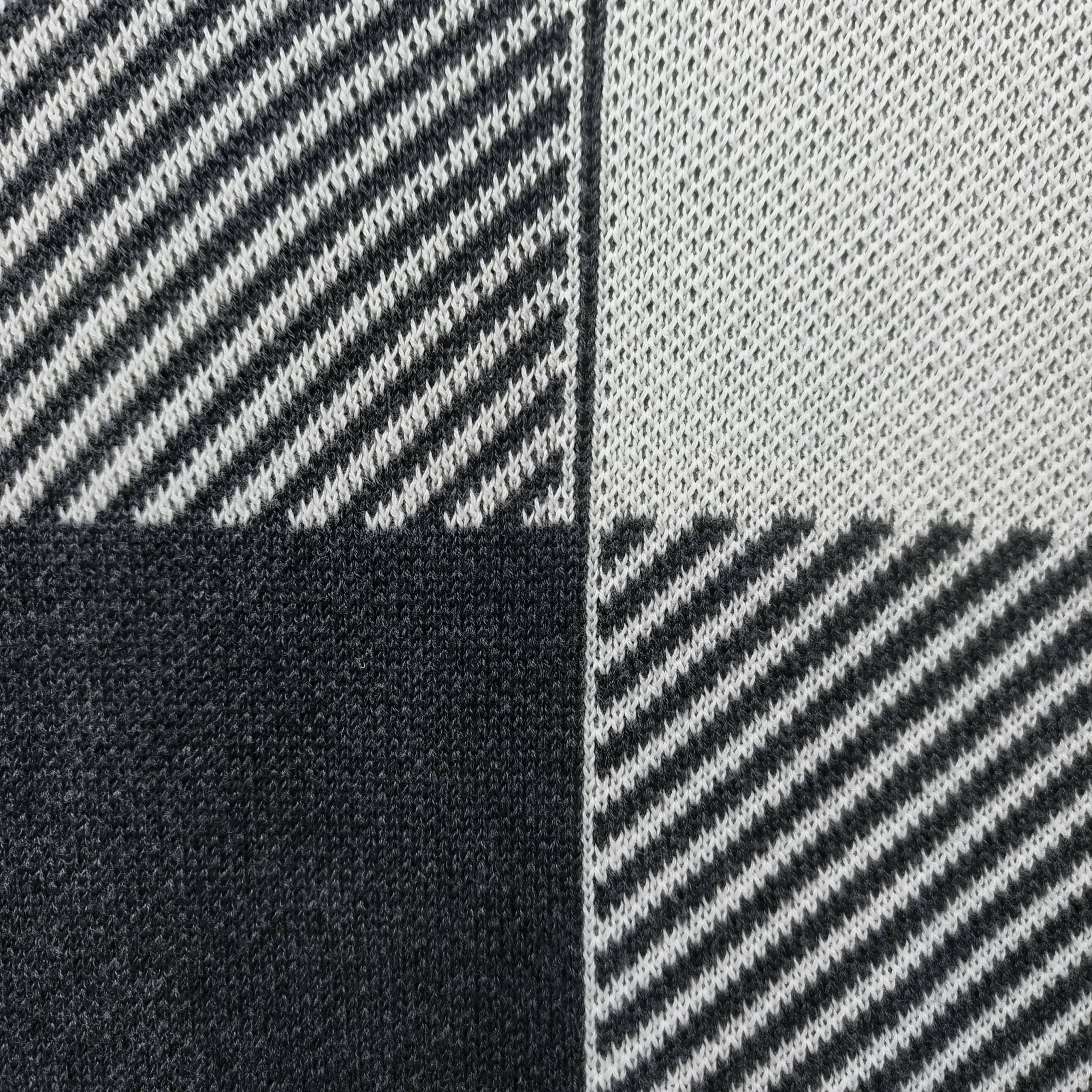

After the yarn is dyed, it is ready to be knitted into a sweater. This is done using specialized Knitting Machines that can accurately replicate the design of the sweater. The high neck of the sweater is created by knitting a separate piece of Fabric that is then attached to the body of the sweater. This process requires a high level of precision and skill to ensure that the neck fits comfortably and looks stylish.

Once the sweater is knitted, it undergoes a process called blocking. This involves wetting the sweater and then stretching it out on a flat surface to dry. Blocking helps to set the shape of the sweater and smooth out any wrinkles or irregularities in the fabric. After blocking, the sweater is carefully inspected for any defects. Any loose threads are trimmed, and any minor repairs are made.

The final step in the production process is labeling. The private label manufacturer attaches a label to the sweater that features the retailer’s brand name and logo. This label serves as a mark of quality and authenticity, assuring customers that the product is made to the highest standards.

The production process of a wool high neck sweater in a private label manufacturing facility is a complex and meticulous process. It requires a high level of skill and attention to detail to ensure that the final product meets the highest quality standards. However, the result is a stylish and comfortable garment that is a testament to the craftsmanship and expertise of the manufacturer.

In conclusion, private label manufacturing offers retailers the opportunity to produce high-quality, branded products that reflect their unique style and brand identity. The production process of a wool high neck sweater is a perfect example of this, demonstrating the care and precision that goes into creating a high-quality garment. Whether you’re a retailer looking to expand your product range or a consumer seeking a stylish and warm sweater, a wool high neck sweater from a private label manufacturer is a great choice.

The Role of Private Label Manufacturing in the Wool High Neck Sweater Industry

Private label manufacturing plays a pivotal role in the wool high neck sweater industry. This business model, which involves a retailer contracting a manufacturer to produce items under the retailer’s brand name, has been instrumental in shaping the industry’s landscape. It has not only allowed retailers to offer unique products that differentiate them from their competitors but also enabled them to control every aspect of the product, from design to pricing.

The wool high neck sweater industry, like many other sectors, has seen a surge in private label manufacturing. This trend can be attributed to several factors. Firstly, the rise of e-commerce has made it easier for retailers to reach a global audience. This has increased competition and made differentiation more critical than ever. Private label manufacturing allows retailers to offer unique wool high neck Sweaters that stand out in a crowded market.

Secondly, consumers are increasingly seeking high-quality, ethically produced clothing. Private label manufacturing gives retailers the control they need to ensure their wool high neck sweaters meet these standards. They can choose to work with manufacturers who use ethically sourced wool, adhere to fair trade practices, and employ skilled artisans who handcraft each sweater to perfection. This level of control is not possible when retailers simply buy and resell products from other brands.

| No. | Commodity Name | Fabric classification | Supply model |

| 2-2 | sweater girls | POL YURETHANE/SPANDEX/LYCRA | Sweater Processing plant |

Moreover, private label manufacturing can be more cost-effective. By working directly with a manufacturer, retailers can eliminate the middlemen and achieve higher profit margins. They can also negotiate better terms, such as lower minimum order quantities, which can be particularly beneficial for small and medium-sized retailers.

However, private label manufacturing is not without its challenges. Finding a reliable manufacturer who can deliver high-quality wool high neck sweaters on time and within budget can be difficult. Retailers also need to invest time and resources into designing their sweaters and building their brand. Despite these challenges, many retailers find that the benefits of private label manufacturing outweigh the drawbacks.

One of the key benefits is the ability to build a strong brand. With private label manufacturing, every wool high neck sweater a retailer sells contributes to their brand image. This can Lead to increased customer loyalty and repeat purchases. In contrast, when retailers sell products from other brands, they are essentially promoting those brands rather than their own.

In conclusion, private label manufacturing plays a crucial role in the wool high neck sweater industry. It allows retailers to differentiate themselves, meet consumer demand for high-quality, ethically produced clothing, and achieve higher profit margins. Despite the challenges involved, many retailers find that the benefits of this business model make it a worthwhile investment. As e-commerce continues to grow and consumer expectations continue to evolve, the role of private label manufacturing in the wool high neck sweater industry is likely to become even more significant.