Table of Contents

Exploring the Production Process of Woollen Sweaters with Hoodies in a Bespoke Factory Complex

The production process of woollen sweaters with hoodies in a bespoke factory complex is a fascinating journey that combines traditional craftsmanship with modern technology. This intricate process involves several stages, each of which contributes to the creation of a high-quality, comfortable, and stylish garment that is perfect for the winter season.

The journey begins with the selection of the finest wool. The quality of the wool is paramount as it determines the comfort, warmth, and durability of the sweater. The wool is sourced from reputable suppliers who adhere to ethical and sustainable farming practices. Once the wool arrives at the factory, it undergoes a thorough inspection to ensure it meets the required standards.

| Number | Product | Fabric selection | Supply model |

| 1-1 | sweater set | BAVE | Sweater Custom-fit |

The next stage involves the cleaning and carding of the wool. This process removes any impurities and aligns the fibres in a parallel direction, making it easier to spin. The cleaned and carded wool is then spun into Yarn using high-speed Spinning Machines. The thickness of the yarn is carefully controlled to ensure consistency in the final product.

Once the yarn is ready, it is dyed to the desired colour. The dyeing process involves immersing the yarn in a bath of colour, which is heated to a specific temperature. The yarn is left in the dye bath for a certain period, after which it is rinsed and dried. The dyed yarn is then wound onto cones, ready for the knitting process.

| Nr. | Product Name | Fabric classification | Supply model |

| 1.1 | mohair men | JUTE | Sweater Custom-fit |

The knitting process is where the magic happens. The cones of yarn are loaded onto computer-controlled Knitting Machines, which are programmed with the design of the sweater. These machines can knit complex patterns and shapes, including the hood of the sweater. The knitting process results in panels for the front, back, and Sleeves of the sweater, as well as the hood.

| Serial Number | Name | Fabric type | Supply model |

| 1 | pullover sweater | ALBUMEN | Sweater Industrial factory |

| Serial Number | Product | Fabric type | Supply model |

| 1. | sueter navidad | POLYNOSIC | Sweater Customizability |

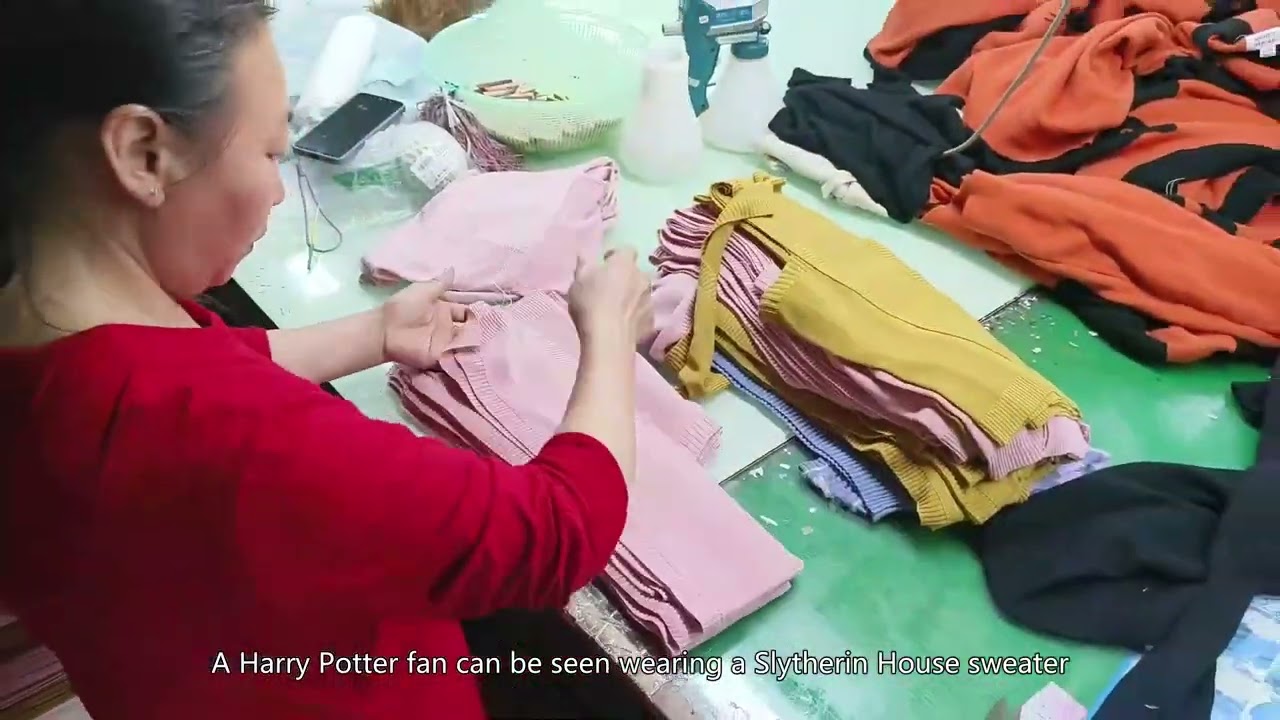

The knitted panels are then passed onto skilled craftsmen for the assembly process. This involves sewing the panels together using industrial Sewing Machines. The craftsmen pay close attention to the alignment of the panels and the quality of the seams to ensure a perfect fit and finish.

| Number | Product Name | Fabric selection | Supply model |

| 1.1 | sweaters online | FABRIC | Sweater Company |

| Serial Number | Product Name | Fabric classification | Supply model |

| one | sweter women | MODAL | Sweater Bespoke |

The assembled sweater then undergoes a rigorous quality control process. This involves checking the sweater for any defects, such as loose threads or misaligned seams. Any sweaters that do not meet the required standards are either repaired or discarded.

The final stage in the production process is the finishing. This involves washing the sweater to remove any residual dye or impurities, and then drying it. The sweater is then pressed to remove any wrinkles and give it a smooth, neat appearance. Finally, the sweater is folded and packaged, ready for distribution.

The production process of woollen sweaters with hoodies in a bespoke factory complex is a testament to the perfect blend of traditional craftsmanship and modern technology. It is a process that requires precision, attention to detail, and a commitment to quality. The result is a stylish, comfortable, and durable garment that is perfect for the winter season.