Table of Contents

Benefits of Using API Standard 5CT Casing Oil Casing Pipe

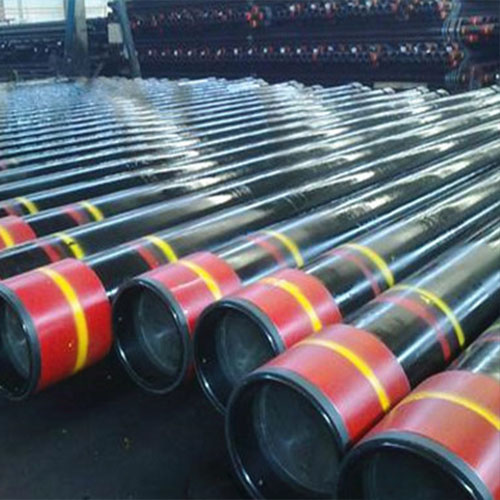

API Standard 5CT casing oil casing pipe is a crucial component in the oil and gas industry. It is used to protect and support the wellbore during drilling and completion operations. This standard sets the requirements for casing and tubing used in oil and gas wells, ensuring that they meet the necessary quality and performance standards.

One of the key benefits of using API Standard 5CT casing oil casing pipe is its durability and strength. These pipes are made from high-quality materials that can withstand the harsh conditions of oil and gas drilling operations. They are designed to resist corrosion, pressure, and other environmental factors, ensuring the integrity of the wellbore.

In addition to their durability, API Standard 5CT casing oil casing pipes are also highly versatile. They come in a variety of sizes and grades to suit different drilling requirements. Whether you are drilling in shallow or deep wells, there is a casing pipe available to meet your needs. This versatility makes it easier for operators to customize their drilling operations and achieve optimal results.

Furthermore, API Standard 5CT casing oil casing pipes are designed to provide a tight seal, preventing any leaks or contamination of the surrounding Environment. This is crucial for maintaining the Safety and efficiency of the drilling operation. By using high-quality casing pipes that meet the API standards, operators can minimize the risk of accidents and ensure compliance with regulatory requirements.

Another benefit of using API Standard 5CT casing oil casing pipes is their cost-effectiveness. While these pipes may have a higher upfront cost compared to other options, their durability and longevity make them a cost-effective choice in the long run. By investing in high-quality casing pipes, operators can reduce the need for frequent replacements and repairs, saving time and money in the process.

Moreover, API Standard 5CT casing oil casing pipes are designed to facilitate the extraction of oil and gas from the wellbore. They provide structural support to the well, allowing for efficient drilling and completion operations. With the right casing pipe in place, operators can maximize production rates and optimize the overall performance of the well.

In conclusion, API Standard 5CT casing oil casing pipes offer a range of benefits to operators in the oil and gas industry. From their durability and strength to their versatility and cost-effectiveness, these pipes are essential for ensuring the success of drilling operations. By using high-quality casing pipes that meet the API standards, operators can enhance the safety, efficiency, and productivity of their drilling operations. Whether drilling in shallow or deep wells, API Standard 5CT casing oil casing pipes provide the necessary support and protection to achieve optimal results.

Comparison of API 5CT N80, J55, K55, P110, and L80 Oil Casing Pipes

API Standard 5CT casing oil casing pipe is a crucial component in the oil and gas industry. It is used to protect the wellbore and ensure the smooth flow of oil or gas from the reservoir to the surface. There are several grades of API 5CT casing pipes available, each with its own unique properties and characteristics. In this article, we will compare the API 5CT N80, J55, K55, P110, and L80 oil casing pipes to help you understand their differences and choose the right one for your specific application.

Let’s start with API 5CT N80 casing pipe. N80 is a medium-strength casing pipe that is commonly used in medium-depth wells. It has a higher tensile strength and better resistance to corrosion than J55 and K55 casing pipes. N80 casing pipe is also known for its excellent weldability, making it a popular choice for casing applications where welding is required.

Next, we have the API 5CT J55 casing pipe. J55 is a low-strength casing pipe that is suitable for shallow wells with low pressure. It is the most commonly used grade of casing pipe due to its low cost and good performance in mild environments. However, J55 casing pipe has lower tensile strength and corrosion resistance compared to N80, making it less suitable for harsher operating conditions.

Moving on to API 5CT K55 casing pipe. K55 is similar to J55 in terms of strength and performance, but it has a higher tensile strength and better resistance to corrosion. K55 casing pipe is often used in medium-depth wells where a balance of strength and cost-effectiveness is required. It is a versatile grade of casing pipe that can be used in a wide range of applications.

Now, let’s discuss API 5CT P110 casing pipe. P110 is a high-strength casing pipe that is suitable for deep wells with high pressure. It has excellent mechanical properties and is highly resistant to corrosion, making it ideal for demanding oil and gas production environments. P110 casing pipe is often used in challenging drilling conditions where other grades of casing pipe may not perform well.

Finally, we have the API 5CT L80 casing pipe. L80 is a medium-strength casing pipe that is commonly used in moderate to high-pressure wells. It has good mechanical properties and excellent resistance to corrosion, making it a reliable choice for a wide range of applications. L80 casing pipe is often used in offshore drilling operations where durability and performance are critical.

In conclusion, the choice of API 5CT casing pipe depends on the specific requirements of your drilling operation. N80, J55, K55, P110, and L80 casing pipes each have their own unique properties and characteristics that make them suitable for different applications. By understanding the differences between these grades of casing pipe, you can select the right one for your drilling project and ensure the success of your oil and gas production operation.