Table of Contents

Benefits of Using Casing Pipe API 5CT H40, J55, K55, M65, L80, C95, N80-1, N80q

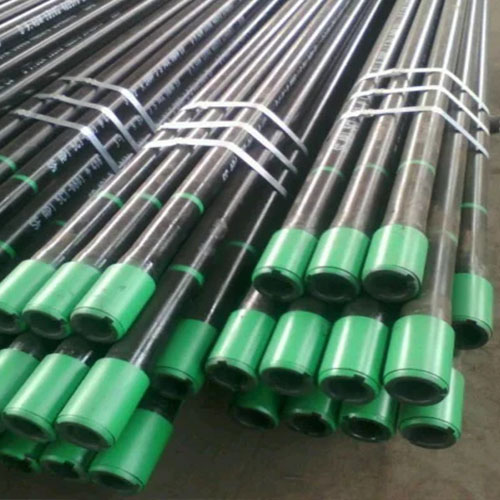

Casing pipes are an essential component in the oil and gas industry, used to line the walls of a borehole to prevent the surrounding soil or rock from collapsing into the wellbore. These pipes are subjected to extreme conditions, including high pressure, temperature, and corrosive environments. Therefore, it is crucial to use high-quality casing pipes that meet industry standards to ensure the Safety and efficiency of oil and gas operations.

One of the most widely used standards for casing pipes is API 5CT, which specifies the technical requirements for casing and tubing used in oil and gas wells. The API 5CT standard covers various grades of casing pipes, including H40, J55, K55, M65, L80, C95, N80-1, and N80q. Each grade has its own unique properties and is designed to withstand specific operating conditions.

One of the key benefits of using casing pipe API 5CT H40, J55, K55, M65, L80, C95, N80-1, N80q is their high strength and durability. These pipes are manufactured using high-quality materials and advanced manufacturing processes to ensure they can withstand the harsh conditions encountered in oil and gas wells. This means that they are less likely to fail or deform under pressure, reducing the risk of costly downtime and potential environmental damage.

In addition to their strength, casing pipes API 5CT H40, J55, K55, M65, L80, C95, N80-1, N80q also offer excellent corrosion resistance. The oil and gas industry operates in corrosive environments, where the presence of hydrogen sulfide, carbon dioxide, and other corrosive substances can cause metal pipes to deteriorate over time. By using casing pipes that are specifically designed to resist corrosion, operators can extend the lifespan of their wells and reduce the need for costly maintenance and repairs.

Furthermore, casing pipes API 5CT H40, J55, K55, M65, L80, C95, N80-1, N80q are designed to provide a tight seal to prevent fluid migration between different geological formations. This is crucial for maintaining well integrity and preventing contamination of groundwater sources. By using high-quality casing pipes that meet API 5CT standards, operators can ensure that their wells are properly sealed and comply with regulatory requirements.

Another benefit of using casing pipes API 5CT H40, J55, K55, M65, L80, C95, N80-1, N80q is their versatility. These pipes are available in a wide range of sizes and specifications to suit different wellbore conditions and drilling techniques. Whether drilling in shallow or deep wells, onshore or offshore, operators can find casing pipes that meet their specific requirements and performance standards.

In conclusion, the benefits of using casing pipes API 5CT H40, J55, K55, M65, L80, C95, N80-1, N80q are clear. These pipes offer high strength, corrosion resistance, tight sealing, and versatility, making them an ideal choice for oil and gas operators looking to ensure the safety and efficiency of their operations. By investing in high-quality casing pipes that meet API 5CT standards, operators can minimize risks, reduce costs, and maximize the productivity of their wells.