Table of Contents

Advantages of Using Galvanized Steel Tubes in Construction Projects

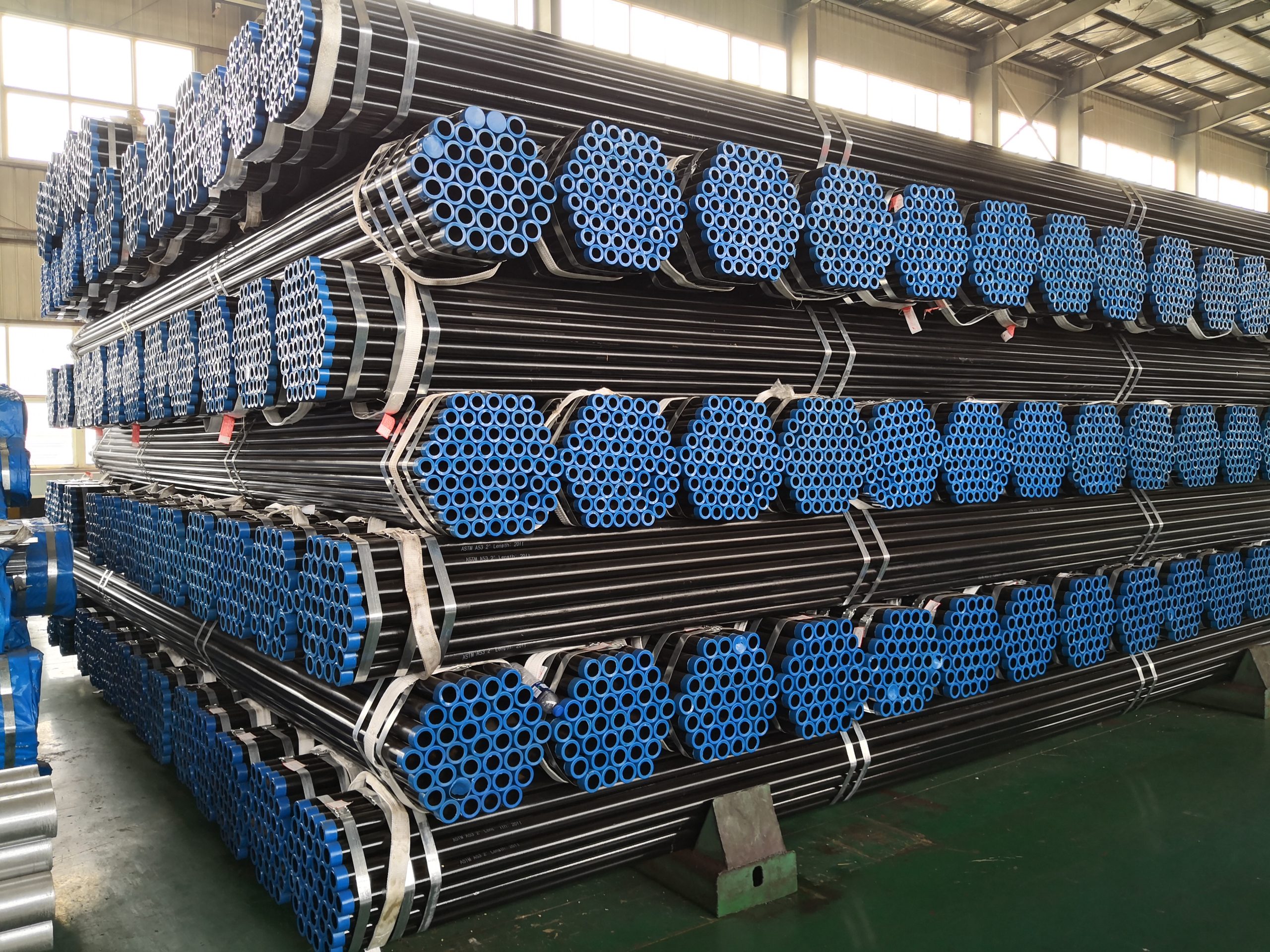

Galvanized steel tubes have become a popular choice in construction projects due to their numerous advantages. One of the main benefits of using galvanized steel tubes is their durability. The Zinc coating on the steel tubes provides protection against corrosion, making them ideal for outdoor applications where they may be exposed to harsh weather conditions. This durability ensures that the steel tubes have a long lifespan, reducing the need for frequent replacements and maintenance.

In addition to their durability, galvanized steel tubes are also known for their strength. The zinc coating adds an extra layer of protection to the steel, making it more resistant to damage and deformation. This strength makes galvanized steel tubes suitable for a wide range of construction projects, from building structures to fencing and piping systems.

Another advantage of using galvanized steel tubes is their cost-effectiveness. While the initial cost of galvanized steel tubes may be slightly higher than other materials, their long lifespan and low maintenance requirements make them a cost-effective choice in the long run. The durability of galvanized steel tubes means that they are less likely to need repairs or replacements, saving both time and money for construction projects.

Furthermore, galvanized steel tubes are easy to work with, making them a popular choice among contractors and builders. The smooth surface of the zinc coating allows for easy welding and fabrication, reducing the time and effort required for installation. This ease of use makes galvanized steel tubes a convenient option for construction projects of all sizes.

In addition to their practical advantages, galvanized steel tubes also offer environmental benefits. The zinc coating on the steel tubes is recyclable, making them a sustainable choice for construction projects. By using galvanized steel tubes, builders can reduce their environmental impact and contribute to a more sustainable construction industry.

Overall, the advantages of using galvanized steel tubes in construction projects are clear. Their durability, strength, cost-effectiveness, ease of use, and environmental benefits make them a versatile and practical choice for a wide range of applications. Whether used in building structures, fencing, piping systems, or other construction projects, galvanized steel tubes offer numerous advantages that make them a popular choice among contractors and builders.

The Process of Hot-DIP Galvanizing and Its Benefits for Steel Pipes

Hot-dip galvanizing is a process that has been used for many years to protect steel from corrosion. In this process, steel is dipped into a bath of molten zinc, which creates a protective coating on the surface of the steel. This coating helps to prevent rust and corrosion, extending the lifespan of the steel and reducing maintenance costs.

One of the main benefits of hot-dip galvanizing is its ability to provide long-lasting protection to steel pipes. The zinc coating that is applied during the galvanizing process forms a barrier between the steel and the Environment, preventing moisture and other corrosive elements from coming into contact with the steel. This helps to prevent rust and corrosion, which can weaken the steel and Lead to costly repairs or replacements.

In addition to providing protection against corrosion, hot-dip galvanizing also enhances the aesthetic appeal of steel pipes. The zinc coating gives the steel a shiny, metallic finish that is visually appealing and can help to improve the overall look of a structure. This makes hot-dip galvanized steel pipes a popular choice for a wide range of applications, including construction, infrastructure, and manufacturing.

Another benefit of hot-dip galvanizing is its cost-effectiveness. While the initial cost of galvanizing steel pipes may be higher than other types of coatings, the long-term savings that are achieved through reduced maintenance and replacement costs make it a cost-effective choice in the long run. Additionally, hot-dip galvanized steel pipes have a longer lifespan than untreated steel pipes, further increasing their cost-effectiveness.

The process of hot-dip galvanizing is relatively simple and straightforward. First, the steel pipes are cleaned to remove any dirt, grease, or other contaminants that may be present on the surface. This is important to ensure that the zinc coating adheres properly to the steel. Once the pipes are clean, they are dipped into a bath of molten zinc at a temperature of around 450 degrees Celsius. The zinc reacts with the steel to form a series of zinc-Iron alloy layers on the surface of the steel, creating a durable and long-lasting coating.

After the pipes have been galvanized, they are inspected to ensure that the coating is uniform and free from defects. Any areas that are not properly coated can be re-dipped to ensure complete coverage. Once the inspection is complete, the galvanized steel pipes are ready to be used in a wide range of applications.

Overall, hot-dip galvanizing is a highly effective and cost-efficient method of protecting steel pipes from corrosion. The process creates a durable and long-lasting coating that helps to extend the lifespan of the steel and reduce maintenance costs. In addition, the shiny finish of galvanized steel pipes adds to their aesthetic appeal, making them a popular choice for a variety of applications. Whether used in construction, infrastructure, or manufacturing, hot-dip galvanized steel pipes offer a reliable and cost-effective solution for protecting steel from corrosion.