Table of Contents

Benefits of Investing in a High-Quality Crankshaft for Industrial Compressor Condensing Units

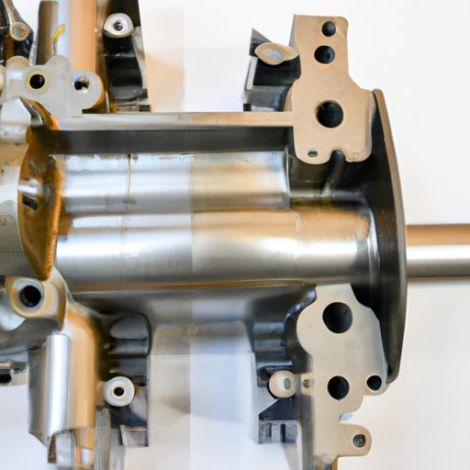

When it comes to industrial compressor condensing units, one of the most crucial components is the crankshaft. The crankshaft plays a vital role in converting the linear motion of the pistons into rotational motion, which is essential for the compressor to function properly. Investing in a high-quality crankshaft for your industrial compressor condensing unit can bring a range of benefits that can ultimately save you time and money in the long run.

One of the primary benefits of investing in a high-quality crankshaft is increased durability and longevity. A well-made crankshaft is designed to withstand the high Levels of stress and pressure that are inherent in industrial compressor operations. This means that it is less likely to break or wear out prematurely, reducing the need for frequent replacements and repairs. By choosing a high-quality crankshaft, you can ensure that your compressor condensing unit operates smoothly and efficiently for an extended period of time.

In addition to durability, a high-quality crankshaft can also improve the overall performance of your industrial compressor condensing unit. A well-designed crankshaft can help to reduce friction and improve the efficiency of the compressor, resulting in lower energy consumption and reduced operating costs. This can Lead to significant savings over time, making it a worthwhile investment for any industrial operation.

Furthermore, a high-quality crankshaft can also contribute to the reliability and stability of your compressor condensing unit. By choosing a crankshaft that is manufactured to the highest standards, you can minimize the risk of unexpected breakdowns and downtime. This can help to ensure that your operations run smoothly and efficiently, allowing you to meet production deadlines and maintain a competitive edge in the market.

When it comes to purchasing a crankshaft for your industrial compressor condensing unit, it is important to choose a reputable supplier that offers genuine, original parts. The Frascold Z40-154Y crankshaft is a popular choice among industrial operators due to its high quality and reliability. This original refrigeration and heat exchange part is designed to meet the specific requirements of industrial compressor condensing units, ensuring optimal performance and longevity.

While the initial cost of investing in a high-quality crankshaft may be higher than opting for a cheaper alternative, the long-term benefits far outweigh the upfront expense. By choosing a crankshaft that is built to last, you can enjoy increased durability, improved performance, and enhanced reliability for your industrial compressor condensing unit. This can ultimately lead to cost savings, increased productivity, and a more efficient operation overall.

In conclusion, investing in a high-quality crankshaft for your industrial compressor condensing unit is a smart decision that can bring a range of benefits to your operation. From increased durability and longevity to improved performance and reliability, a well-made crankshaft can make a significant difference in the efficiency and effectiveness of your compressor. By choosing a reputable supplier and opting for genuine, original parts like the Frascold Z40-154Y crankshaft, you can ensure that your industrial compressor condensing unit operates at its best for years to come.

How to Identify and Replace a Faulty Crankshaft in a Frascold Z40-154Y Refrigeration & Heat Exchange Part

When it comes to Industrial Compressors, the crankshaft is a crucial component that plays a key role in the overall functioning of the unit. In the case of the Frascold Z40-154Y refrigeration and heat exchange part, the crankshaft is responsible for converting the linear motion of the pistons into rotational motion, which in turn drives the compressor. If the crankshaft is faulty or damaged, it can lead to a breakdown of the entire compressor unit, resulting in costly repairs and downtime.

Identifying a faulty crankshaft in a Frascold Z40-154Y compressor can be a challenging task, especially for those who are not familiar with the inner workings of industrial compressors. However, there are a few key signs that can indicate a problem with the crankshaft. One of the most common symptoms of a faulty crankshaft is unusual noises coming from the compressor unit, such as knocking or grinding sounds. These noises are often a result of the crankshaft Bearings wearing out or the crankshaft itself becoming misaligned.

Another sign of a faulty crankshaft is a decrease in the overall performance of the compressor unit. If the compressor is not able to maintain the desired pressure or temperature levels, it could be due to a malfunctioning crankshaft. In some cases, a faulty crankshaft can also cause the compressor to vibrate excessively, which can lead to further damage to other components of the unit.

If you suspect that the crankshaft in your Frascold Z40-154Y compressor is faulty, it is important to take action promptly to avoid further damage to the unit. The first step in replacing a faulty crankshaft is to identify the exact model of the compressor and locate the appropriate replacement part. The Frascold Z40-154Y crankshaft is a specialized component that is designed specifically for this model of compressor, so it is important to ensure that you are purchasing the correct part.

Once you have obtained the replacement crankshaft, the next step is to remove the old crankshaft from the compressor unit. This process can be complex and may require the use of specialized tools and equipment. It is important to follow the manufacturer’s instructions carefully to avoid causing damage to other components of the compressor.

Once you have obtained the replacement crankshaft, the next step is to remove the old crankshaft from the compressor unit. This process can be complex and may require the use of specialized tools and equipment. It is important to follow the manufacturer’s instructions carefully to avoid causing damage to other components of the compressor.

After removing the old crankshaft, the new crankshaft can be installed in its place. It is important to ensure that the new crankshaft is properly aligned and secured in place to prevent any future issues. Once the new crankshaft is installed, it is recommended to test the compressor unit to ensure that it is functioning properly.

In conclusion, identifying and replacing a faulty crankshaft in a Frascold Z40-154Y compressor is a critical task that should be approached with caution and attention to detail. By following the steps outlined in this article and seeking professional assistance if needed, you can ensure that your compressor unit continues to operate efficiently and effectively.