Table of Contents

Benefits of Using Genuine GB276-82 4G116 Bulldozer Parts

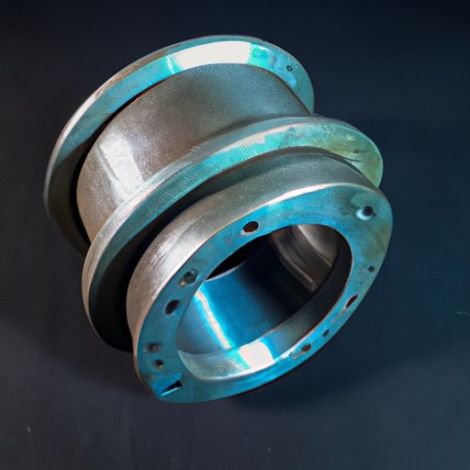

When it comes to maintaining heavy machinery like Bulldozers, using genuine parts is crucial for ensuring optimal performance and longevity. One essential component of a bulldozer is the hydraulic motor, which plays a vital role in powering various functions of the machine. The GB276-82 4G116 bulldozer parts bearing hydraulic motor is a high-quality, reliable component that is designed to meet the specific requirements of this heavy-duty equipment.

Using genuine GB276-82 4G116 bulldozer parts bearing hydraulic motor offers several benefits that can help improve the overall performance and efficiency of the machine. One of the primary advantages of using genuine parts is the assurance of quality and compatibility. Genuine parts are designed and manufactured to meet the exact specifications of the equipment, ensuring a perfect fit and seamless integration with the existing components. This not only helps prevent potential issues that may arise from using inferior or incompatible parts but also ensures optimal performance and reliability.

Using genuine GB276-82 4G116 bulldozer parts bearing hydraulic motor offers several benefits that can help improve the overall performance and efficiency of the machine. One of the primary advantages of using genuine parts is the assurance of quality and compatibility. Genuine parts are designed and manufactured to meet the exact specifications of the equipment, ensuring a perfect fit and seamless integration with the existing components. This not only helps prevent potential issues that may arise from using inferior or incompatible parts but also ensures optimal performance and reliability.

Another benefit of using genuine GB276-82 4G116 bulldozer parts bearing hydraulic motor is durability and longevity. Genuine parts are made from high-quality materials and undergo rigorous testing to ensure they can withstand the demanding conditions of heavy-duty equipment like bulldozers. This means that genuine parts are more likely to last longer and require less frequent replacement, ultimately saving time and money in the long run.

In addition to quality and durability, using genuine GB276-82 4G116 bulldozer parts bearing hydraulic motor can also help maintain the resale value of the equipment. When it comes time to sell or trade in the bulldozer, having genuine parts installed can increase its market value and make it more attractive to potential buyers. Genuine parts are a sign of proper maintenance and care, which can instill confidence in the buyer and help justify a higher asking price.

Furthermore, using genuine GB276-82 4G116 bulldozer parts bearing hydraulic motor can also help prevent potential Safety hazards. Inferior or counterfeit parts may not meet the same safety standards as genuine parts, increasing the risk of malfunctions or failures that could Lead to accidents or injuries. By using genuine parts, operators can have peace of mind knowing that their equipment is operating safely and efficiently.

Overall, the benefits of using genuine GB276-82 4G116 bulldozer parts bearing hydraulic motor are clear. From quality and compatibility to durability and safety, genuine parts offer a range of advantages that can help improve the performance and longevity of the equipment. Whether it’s for maintenance, repairs, or upgrades, investing in genuine parts is a wise decision that can pay off in the long run. So, when it comes to keeping your bulldozer running smoothly, trust in genuine parts to deliver the best results.

How to Properly Maintain and Replace Bearings in the Hydraulic Motor of a GB276-82 4G116 Bulldozer

The hydraulic motor is a crucial component of a bulldozer, responsible for converting hydraulic pressure into mechanical power to drive the machine. Within the hydraulic motor, bearings play a vital role in supporting the rotating Shafts and ensuring smooth operation. Proper maintenance and timely replacement of bearings are essential to keep the hydraulic motor functioning efficiently and prevent costly breakdowns.

One common type of bulldozer that utilizes a hydraulic motor is the GB276-82 4G116. This heavy-duty machine requires regular maintenance to ensure optimal performance on the job site. When it comes to the bearings in the hydraulic motor of the GB276-82 4G116 bulldozer, there are several key steps to follow to properly maintain and replace them.

First and foremost, regular inspection of the bearings is crucial to identify any signs of wear or damage. This can include unusual noises, vibrations, or excessive heat coming from the hydraulic motor. If any of these symptoms are present, it is important to address them promptly to prevent further damage to the bearings and other components of the hydraulic motor.

When it comes time to replace the bearings in the hydraulic motor of the GB276-82 4G116 bulldozer, it is essential to use high-quality, OEM-approved parts. This will ensure proper fit and function, as well as longevity and reliability. One common type of bearing used in Hydraulic Motors is the ball bearing, which consists of a series of Balls encased in a ring. These bearings are designed to handle high speeds and heavy loads, making them ideal for use in hydraulic motors.

To replace the bearings in the hydraulic motor of the GB276-82 4G116 bulldozer, start by disconnecting the hydraulic lines and removing the motor from the machine. Carefully disassemble the motor, taking note of the position and orientation of each bearing. Use a bearing puller or press to remove the old bearings, being careful not to damage the shaft or housing.

Once the old bearings have been removed, thoroughly clean the shaft and housing to remove any debris or contaminants. Apply a thin layer of grease or oil to the new bearings before installing them, ensuring proper lubrication and smooth operation. Carefully press the new bearings into place, making sure they are seated correctly and securely.

After the new bearings have been installed, reassemble the hydraulic motor and reattach it to the bulldozer. Check for proper alignment and smooth operation before reconnecting the hydraulic lines and testing the machine. It is important to monitor the performance of the hydraulic motor after bearing replacement to ensure everything is functioning as it should.

In conclusion, proper maintenance and timely replacement of bearings in the hydraulic motor of a GB276-82 4G116 bulldozer are essential to keep the machine running smoothly and efficiently. By following these steps and using high-quality, OEM-approved parts, you can ensure the longevity and reliability of your bulldozer’s hydraulic motor. Remember to regularly inspect the bearings for signs of wear or damage, and address any issues promptly to prevent costly breakdowns. With proper care and maintenance, your GB276-82 4G116 bulldozer will continue to perform at its best on the job site.