Table of Contents

Benefits of Using Hand Held Plastic Extrusion Welder for Small Welding Projects

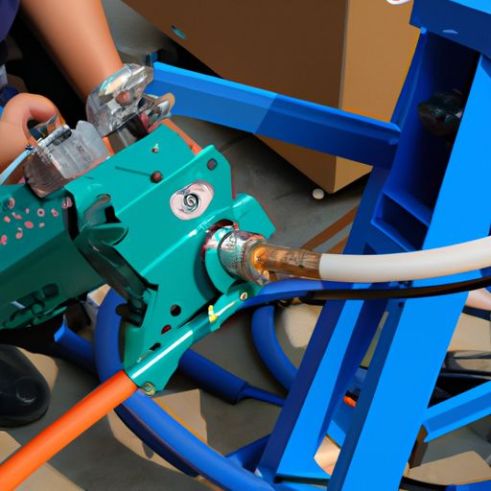

Plastic extrusion welding is a popular method used in various industries for joining thermoplastic materials. One of the most convenient tools for this process is the hand-held plastic extrusion welder. These compact devices are perfect for small welding projects and offer a range of benefits that make them a valuable addition to any workshop.

Plastic extrusion welding is a popular method used in various industries for joining thermoplastic materials. One of the most convenient tools for this process is the hand-held plastic extrusion welder. These compact devices are perfect for small welding projects and offer a range of benefits that make them a valuable addition to any workshop.

One of the main advantages of using a hand-held plastic extrusion welder is its portability. These devices are lightweight and easy to carry around, making them ideal for on-site welding jobs. Whether you are working in a tight space or need to move around frequently, a hand-held extrusion welder allows you to work with ease and precision.

In addition to portability, hand-held extrusion welders are also easy to use. They come with simple controls and are designed for user-friendly operation. Even beginners can quickly learn how to use these devices and achieve professional results. This makes them a great choice for DIY enthusiasts and small businesses looking to save time and money on welding projects.

Another benefit of using a hand-held plastic extrusion welder is its versatility. These devices can be used for a wide range of welding applications, including joining pipes, sheets, and profiles. Whether you are working with HDPE, PP, PVC, or other thermoplastics, a hand-held extrusion welder can help you achieve strong and durable welds.

Furthermore, hand-held extrusion welders offer precise control over the welding process. With adjustable temperature and speed settings, you can tailor the weld to suit your specific requirements. This level of control ensures that you can achieve consistent results every time, regardless of the complexity of the project.

When it comes to small welding projects, time is often of the essence. Hand-held extrusion welders are designed to work quickly and efficiently, allowing you to complete your projects in a timely manner. This can help you save valuable time and resources, making your workflow more efficient and productive.

In addition to time savings, hand-held extrusion welders also offer cost benefits. These devices are affordable and require minimal maintenance, making them a cost-effective solution for small welding projects. By investing in a hand-held extrusion welder, you can enjoy long-term savings and a high return on investment.

Overall, hand-held plastic extrusion welders are a valuable tool for small welding projects. Their portability, ease of use, versatility, precise control, efficiency, and cost-effectiveness make them a popular choice among professionals and hobbyists alike. Whether you are working on a DIY project at home or completing a commercial welding job on-site, a hand-held extrusion welder can help you achieve professional results with ease.

How to Choose the Best HDPE Extrusion Welding Machine Supplier for SWT-NS610C Extrusion Welder for Pipe

When it comes to choosing the best HDPE extrusion welding machine supplier for the SWT-NS610C extrusion welder for pipe, there are several factors to consider. The quality of the machine, the reputation of the supplier, and the level of customer service are all important aspects to take into account.

First and foremost, it is crucial to ensure that the HDPE extrusion welding machine you are considering is of high quality. The SWT-NS610C extrusion welder for pipe is a precision tool that requires precision engineering to function properly. Look for a supplier that has a reputation for producing reliable and durable machines that can withstand the rigors of daily use.

In addition to quality, the reputation of the supplier is also important. Look for a supplier that has a track record of providing excellent customer service and support. A reputable supplier will be able to answer any questions you may have about the machine, provide training and technical support, and offer assistance with any issues that may arise.

Customer service is another key factor to consider when choosing a supplier for the SWT-NS610C extrusion welder for pipe. Look for a supplier that is responsive to your needs and is willing to go the extra mile to ensure your satisfaction. A supplier that is easy to reach, whether by phone, email, or in person, is essential for ensuring that you have a positive experience with your extrusion welding machine.

When researching potential suppliers, be sure to ask for references from past customers. This will give you an idea of the level of satisfaction that other customers have had with the supplier and their machines. Additionally, look for online reviews and testimonials to get a sense of the supplier’s reputation in the industry.

Price is also a consideration when choosing a supplier for the SWT-NS610C extrusion welder for pipe. While it is important to find a machine that fits within your budget, it is equally important to ensure that you are getting a quality product. Be wary of suppliers that offer significantly lower prices than their competitors, as this may be a sign of inferior quality.

In conclusion, choosing the best HDPE extrusion welding machine supplier for the SWT-NS610C extrusion welder for pipe requires careful consideration of several factors. Quality, reputation, customer service, and price are all important aspects to take into account when making your decision. By doing your research, asking for references, and carefully evaluating your options, you can find a supplier that meets your needs and provides you with a reliable and durable extrusion welding machine.