Table of Contents

Advantages of High Quality Seamless Casing Pipe in Oil and Gas Industry

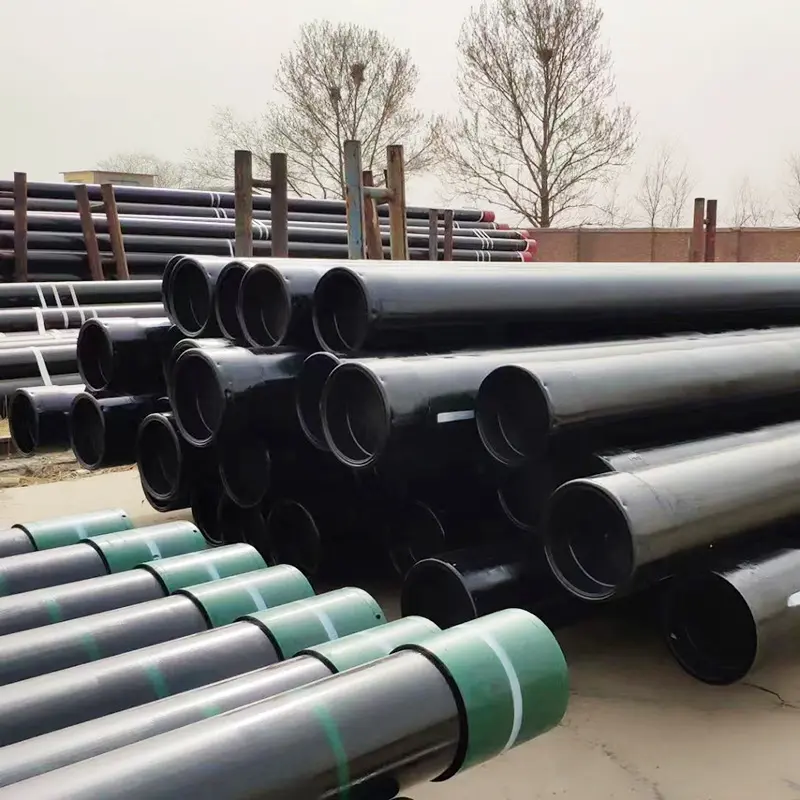

High Quality Seamless Casing Pipe: Ensuring Efficiency in the Oil and Gas Industry

In the realm of the oil and gas industry, efficiency and reliability are paramount. Every component of the extraction and transportation process must be meticulously engineered to withstand harsh conditions and deliver consistent performance. Among these critical components, seamless casing pipes stand as silent sentinels, supporting the integrity of oil wells and ensuring the smooth flow of resources. In this article, we delve into the advantages of high-quality seamless casing pipes and their indispensable role in the oil and gas sector.

At the heart of seamless casing pipes lies a commitment to durability and structural integrity. Unlike their welded counterparts, seamless pipes are manufactured through a process that eliminates the need for welding seams, thereby minimizing weak points in the material. This seamless construction not only enhances the overall strength of the pipe but also reduces the likelihood of corrosion and structural failure over time.

In addition to their robust construction, high-quality seamless casing pipes boast superior dimensional accuracy. Precise measurements and uniformity in thickness ensure a snug fit within oil wells, effectively containing the hydrocarbons and preventing leaks. This level of precision is crucial in environments where even the slightest deviation from specification can result in costly setbacks and environmental hazards.

Furthermore, seamless casing pipes offer unparalleled resistance to high pressure and extreme temperatures. As oil and gas reserves are often found in geologically challenging locations, such as deep-sea drilling sites or arctic regions, the ability of casing pipes to withstand varying environmental conditions is indispensable. By maintaining their integrity under such duress, seamless casing pipes contribute to the Safety of personnel and the preservation of natural habitats.

Moreover, the seamless nature of these pipes facilitates smoother fluid flow, optimizing the efficiency of oil and gas extraction processes. Without the disruptions caused by welding seams, friction within the pipe is minimized, allowing resources to be transported more efficiently from the wellhead to processing facilities. This seamless flow not only increases productivity but also reduces energy consumption and operational costs.

Beyond their functional advantages, high-quality seamless casing pipes offer peace of mind to stakeholders across the oil and gas supply chain. Rigorous quality control measures and adherence to industry standards ensure that each pipe meets the highest Levels of performance and reliability. This reliability translates into fewer maintenance requirements and longer service life, ultimately enhancing the return on investment for operators and investors alike.

In conclusion, the advantages of high-quality seamless casing pipes in the oil and gas industry are manifold. From their robust construction to their precise dimensions and resistance to extreme conditions, these pipes play a vital role in ensuring the efficiency and reliability of oil and gas operations worldwide. As technology continues to evolve and demand for energy grows, the importance of seamless casing pipes as a cornerstone of the industry is only set to increase. By investing in quality and innovation, stakeholders can secure a sustainable future for the oil and gas sector while meeting the world’s energy needs.