Table of Contents

How to Repair a Hot Plate Honton System Board for Automatic Welding Machine

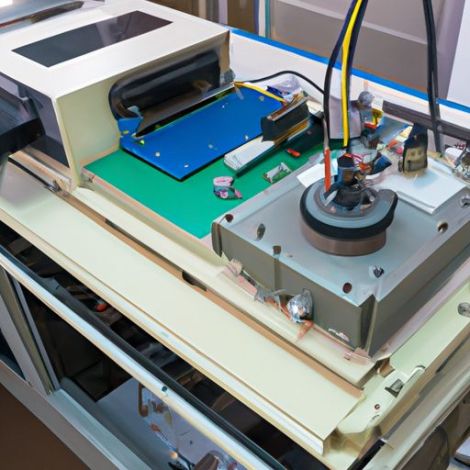

Hot Plate Honton Repair System Board Automatic Welding Machine 220V 110V 600W HT-R260 BGA reballing reflow oven is a crucial piece of equipment for those in the electronics industry. This machine is used for reflow soldering, which is a process that involves melting solder to create a strong bond between components on a circuit board. However, like any piece of machinery, the hot plate Honton system board can experience issues that require repair.

One common problem that users may encounter with the hot plate Honton system board is a malfunctioning automatic welding machine. This can be caused by a variety of factors, such as a faulty circuit board or a damaged heating element. In order to repair this issue, it is important to first diagnose the problem and then take the necessary steps to fix it.

One of the first things to check when troubleshooting a malfunctioning automatic welding machine is the system board. This is the central component of the hot plate Honton system board and is responsible for controlling the various functions of the machine. If the system board is damaged or malfunctioning, it can cause the automatic welding machine to not work properly.

To repair the system board, it is important to first power off the machine and unplug it from the electrical outlet. Next, carefully remove the system board from the machine and inspect it for any visible signs of damage, such as burnt components or loose connections. If any damage is found, it may be necessary to replace the damaged components or repair any loose connections.

Once the system board has been inspected and any necessary repairs have been made, it can be reinstalled in the hot plate Honton system board. It is important to follow the manufacturer’s instructions for reinstallation to ensure that the system board is properly connected and functioning correctly.

In addition to repairing the system board, it may also be necessary to repair the heating element of the hot plate Honton system board. The heating element is responsible for heating the solder paste to the correct temperature during the reflow soldering process. If the heating element is damaged or malfunctioning, it can cause the automatic welding machine to not heat up properly.

To repair the heating element, it is important to first power off the machine and unplug it from the electrical outlet. Next, carefully remove the heating element from the machine and inspect it for any visible signs of damage, such as burnt wires or a cracked heating element. If any damage is found, it may be necessary to replace the heating element with a new one.

To repair the heating element, it is important to first power off the machine and unplug it from the electrical outlet. Next, carefully remove the heating element from the machine and inspect it for any visible signs of damage, such as burnt wires or a cracked heating element. If any damage is found, it may be necessary to replace the heating element with a new one.

Once the heating element has been replaced, it can be reinstalled in the hot plate Honton system board. Again, it is important to follow the manufacturer’s instructions for reinstallation to ensure that the heating element is properly connected and functioning correctly.

In conclusion, repairing a hot plate Honton system board for an automatic welding machine is a complex process that requires careful diagnosis and attention to detail. By following the steps outlined in this article, users can effectively troubleshoot and repair issues with their hot plate Honton system board, ensuring that their automatic welding machine is functioning properly and producing high-quality solder joints.