Table of Contents

Benefits of Using SUS 316L, 201, and 304 Stainless Steel Pipes in Inox Factory

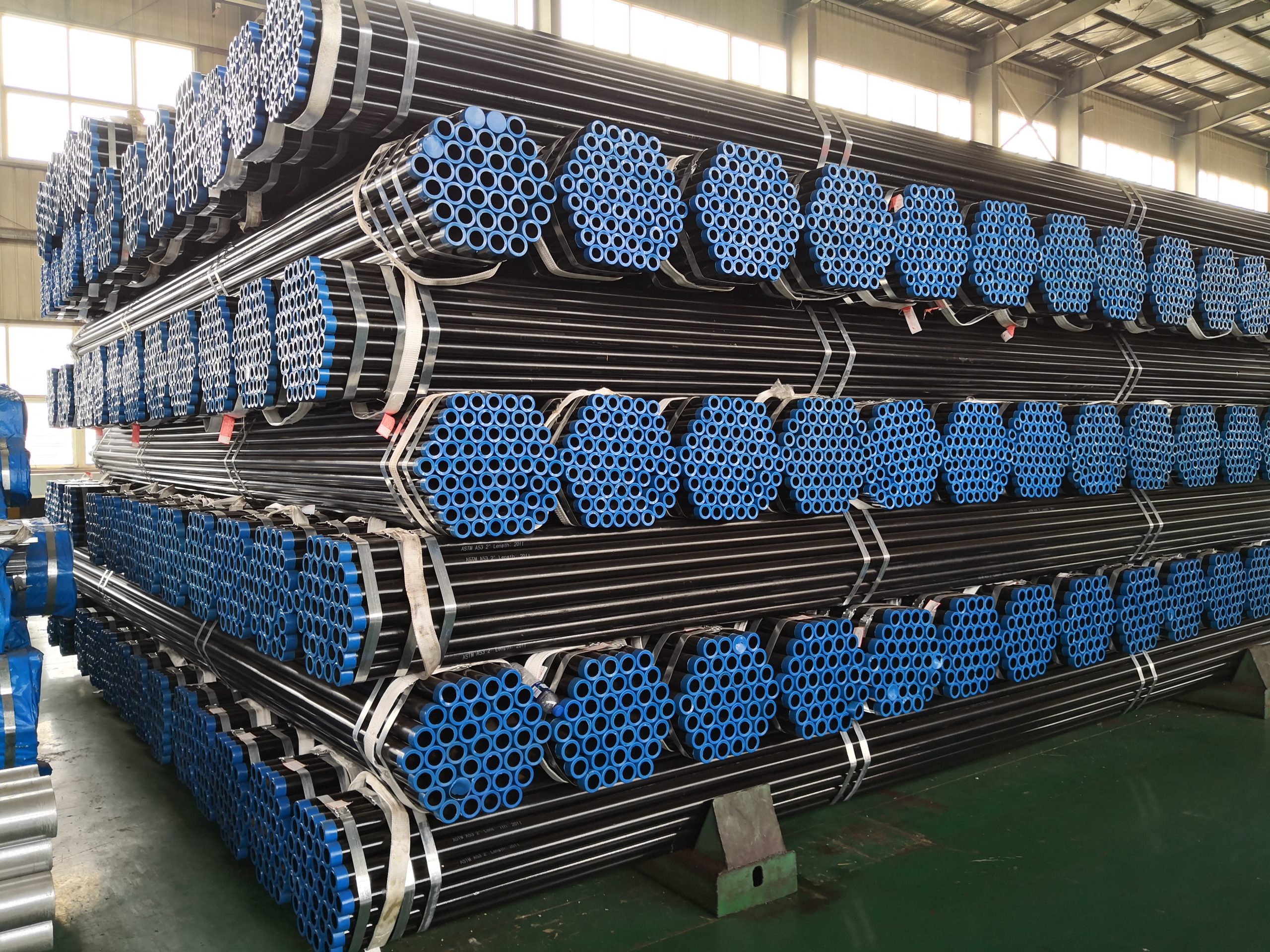

Stainless Steel Pipes are a crucial component in various industries, including the Inox Factory. The choice of material for these pipes is essential to ensure durability, longevity, and resistance to corrosion. Among the different types of stainless steel available, SUS 316L, 201, and 304 are some of the most commonly used grades in the manufacturing of stainless steel pipes.

SUS 316L stainless steel is a low-carbon version of SUS 316, which contains Molybdenum for added corrosion resistance. This grade is highly resistant to pitting and crevice corrosion in chloride environments, making it ideal for use in marine applications, chemical processing, and pharmaceutical industries. The addition of molybdenum also improves the overall strength and toughness of the material, making it suitable for high-pressure and high-temperature applications.

SUS 201 stainless steel is a cost-effective alternative to SUS 304, offering good corrosion resistance and formability. This grade is commonly used in household appliances, kitchenware, and automotive trim due to its aesthetic appeal and ease of fabrication. While not as corrosion-resistant as SUS 316L or 304, SUS 201 is still a reliable choice for applications where moderate corrosion resistance is sufficient.

SUS 304 stainless steel is the most widely used grade in the stainless steel industry, known for its excellent corrosion resistance, formability, and weldability. This grade is suitable for a wide range of applications, including food processing, dairy, and brewing industries, where hygiene and cleanliness are paramount. The high chromium content in SUS 304 provides a protective Oxide layer that prevents rusting and staining, making it a popular choice for both indoor and outdoor applications.

The Inox Factory benefits from using SUS 316L, 201, and 304 stainless steel pipes in various ways. Firstly, these grades offer superior corrosion resistance compared to other materials, ensuring the longevity and reliability of the piping system. This is particularly important in industries where exposure to harsh Chemicals, high temperatures, or corrosive environments is common.

Secondly, the high strength and durability of SUS 316L, 201, and 304 stainless steel pipes make them suitable for demanding applications that require resistance to pressure, vibration, and mechanical stress. This ensures that the piping system can withstand the rigors of daily operation without compromising performance or Safety.

Furthermore, the aesthetic appeal of stainless steel pipes adds value to the overall appearance of the Inox Factory. The sleek and modern look of stainless steel complements the industrial setting, creating a professional and clean Environment for workers and visitors alike.

In conclusion, the use of SUS 316L, 201, and 304 stainless steel pipes in the Inox Factory offers numerous benefits, including superior corrosion resistance, high strength, durability, and aesthetic appeal. These grades are well-suited for a wide range of applications in various industries, making them a versatile and reliable choice for piping systems. By investing in quality stainless steel pipes, the Inox Factory can ensure the efficiency, safety, and longevity of its operations for years to come.