Table of Contents

Benefits of Using ABS Plastic for Injection Molding

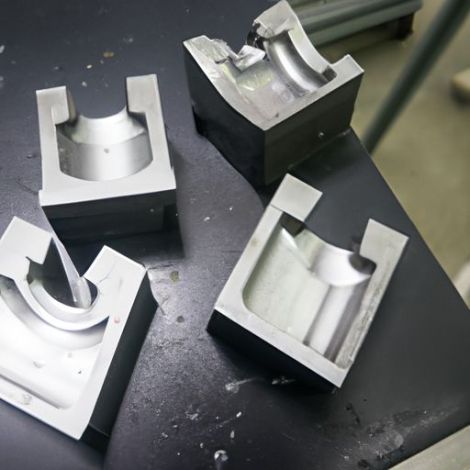

ABS plastic injection molding is a popular manufacturing process that involves injecting molten ABS plastic into a mold cavity. This process allows for the production of high-quality, custom parts with a wide range of shapes and sizes. ABS plastic is a versatile material that offers many benefits for injection molding projects.

One of the main benefits of using ABS plastic for injection molding is its strength and durability. ABS plastic is known for its high impact resistance, making it ideal for parts that need to withstand heavy use or harsh environments. This material is also resistant to heat and Chemicals, making it suitable for a variety of applications.

Another advantage of ABS plastic is its versatility. ABS plastic can be easily molded into complex shapes and intricate designs, allowing for the production of custom parts with precision and accuracy. This material can also be easily colored and finished, giving manufacturers the flexibility to create parts in a wide range of colors and textures.

ABS plastic is also a cost-effective option for injection molding projects. This material is readily available and relatively inexpensive, making it a cost-effective choice for large-scale production runs. ABS plastic is also easy to work with, reducing the time and labor required to produce parts.

In addition to its strength, durability, versatility, and cost-effectiveness, ABS plastic is also environmentally friendly. ABS plastic is recyclable and can be reused in the production of new parts, reducing waste and minimizing the environmental impact of injection molding projects.

Overall, ABS plastic offers a wide range of benefits for injection molding projects. Its strength, durability, versatility, cost-effectiveness, and environmental friendliness make it an ideal choice for manufacturers looking to produce high-quality, custom parts.

When choosing a molding service for your ABS plastic injection molding project, it is important to work with a reputable and experienced company. A professional molding service will have the expertise and equipment needed to produce high-quality parts that meet your specifications and requirements.

By partnering with a reliable molding service, you can ensure that your ABS plastic injection molding project is completed efficiently and effectively. Whether you are producing parts for the automotive, electronics, medical, or consumer goods industries, ABS plastic injection molding offers a wide range of benefits that can help you achieve your manufacturing goals.

In conclusion, ABS plastic injection molding is a versatile and cost-effective manufacturing process that offers many benefits for producing custom parts. By choosing ABS plastic for your injection molding project and working with a reputable molding service, you can create high-quality parts that meet your specifications and requirements.