Table of Contents

The Importance of Quality Control in OCTG Manufacturing

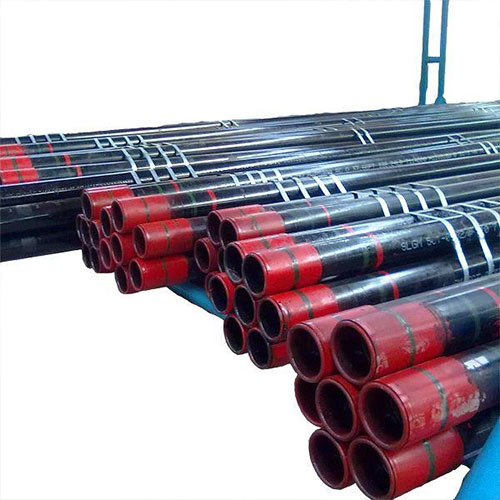

Oil Country Tubular Goods (OCTG) are essential components in the oil and gas industry, used in drilling and production operations. As such, the quality of OCTG products is of utmost importance to ensure the Safety and efficiency of these operations. Quality control in OCTG manufacturing plays a crucial role in ensuring that the products meet industry standards and specifications.

One of the key aspects of quality control in OCTG manufacturing is the inspection of raw materials. The quality of the steel used in OCTG products is critical to their performance in harsh drilling environments. Manufacturers must carefully inspect the chemical composition and mechanical properties of the steel to ensure that it meets the required standards. Any deviation from these standards could result in product failure and potentially catastrophic consequences.

In addition to raw material inspection, quality control in OCTG manufacturing also involves rigorous testing of the finished products. This includes non-destructive testing methods such as ultrasonic testing, magnetic particle testing, and visual inspection. These tests help identify any defects or imperfections in the products that could compromise their integrity during use. By conducting thorough testing, manufacturers can ensure that only high-quality OCTG products are delivered to customers.

Furthermore, quality control in OCTG manufacturing extends beyond the production process to include storage and transportation. OCTG products are often stored in outdoor yards or Warehouses before being transported to drilling sites. Proper storage conditions are essential to prevent corrosion and damage to the products. Manufacturers must implement measures to protect OCTG products from environmental factors such as moisture, temperature fluctuations, and physical damage.

When it comes to transportation, quality control measures must be in place to ensure that OCTG products are handled and shipped safely. Proper packaging and securing of the products are essential to prevent damage during transit. Manufacturers must also work closely with logistics providers to ensure that OCTG products are delivered to customers in a timely and efficient manner.

Overall, quality control in OCTG manufacturing is essential to uphold the reputation of manufacturers and ensure the safety and reliability of their products. By implementing strict quality control measures throughout the production process, manufacturers can minimize the risk of product failures and costly rework. Customers can have confidence in the quality of OCTG products they receive, knowing that they have been thoroughly inspected and tested to meet industry standards.

In conclusion, quality control in OCTG manufacturing is a critical aspect of ensuring the performance and reliability of these essential products in the oil and gas industry. By focusing on raw material inspection, product testing, storage, and transportation, manufacturers can deliver high-quality OCTG products that meet the stringent requirements of the industry. Quality control is not just a regulatory requirement but a commitment to excellence and customer satisfaction.