Table of Contents

Benefits of Using Original New FUJI CLAMPER Production in SMT Machines

In the world of electronic manufacturing, precision and efficiency are key factors in producing high-quality products. One crucial component in surface mount technology (SMT) machines is the clamping mechanism, which securely holds electronic components in place during the assembly process. When it comes to replacing or upgrading this essential part, opting for original new FUJI CLAMPER production can offer a range of benefits for manufacturers.

One of the primary advantages of using original new FUJI CLAMPER production in SMT machines is the assurance of quality and compatibility. These parts are specifically designed and manufactured by FUJI, the original equipment manufacturer (OEM), to meet the exact specifications and requirements of their machines. This ensures a perfect fit and seamless integration, minimizing the risk of malfunctions or errors during operation.

Furthermore, original new FUJI CLAMPER production is made from high-quality materials and undergoes rigorous testing to ensure durability and reliability. This means that manufacturers can trust these parts to perform consistently and effectively over an extended period, reducing the need for frequent replacements and maintenance. By investing in quality components, manufacturers can improve the overall efficiency and productivity of their SMT machines.

Another benefit of using original new FUJI CLAMPER production is the access to technical support and expertise from the manufacturer. FUJI has a team of knowledgeable engineers and technicians who can provide guidance and assistance with installation, troubleshooting, and maintenance of their products. This level of support can be invaluable for manufacturers looking to optimize the performance of their SMT machines and minimize downtime.

In addition, original new FUJI CLAMPER production is backed by a warranty from the manufacturer, providing added peace of mind for manufacturers. In the unlikely event that a part fails or malfunctions, FUJI will replace or repair the component at no additional cost, ensuring that production can resume quickly and smoothly. This warranty coverage can help manufacturers save time and money in the long run, as they can rely on the support of the OEM to address any issues that may arise.

Furthermore, using original new FUJI CLAMPER production can also help manufacturers maintain the resale value of their SMT machines. When it comes time to upgrade or replace equipment, having genuine FUJI parts installed can increase the market value of the machines. Potential buyers are more likely to trust machines that have been maintained with original components, as they are seen as more reliable and durable.

Overall, the benefits of using original new FUJI CLAMPER production in SMT machines are clear. From quality and compatibility to technical support and warranty coverage, manufacturers can trust these components to enhance the performance and longevity of their equipment. By investing in genuine FUJI parts, manufacturers can improve efficiency, reduce downtime, and ultimately, achieve better results in electronic manufacturing.

How to Properly Maintain FUJI Pick and Place Machines for Electronic Products Machinery

FUJI pick and place machines are essential tools in the electronic products manufacturing industry. These machines are responsible for accurately placing electronic components onto circuit Boards, ensuring that the final product functions correctly. To keep FUJI pick and place machines running smoothly and efficiently, proper maintenance is crucial.

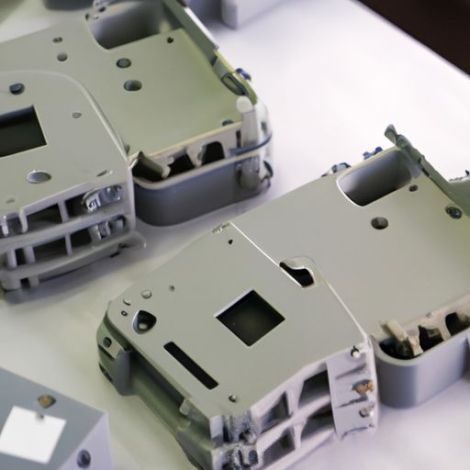

One of the key components of a FUJI pick and place machine is the FUJI CLAMPER production smt machine AA34T02. This part is responsible for securely holding electronic components in place during the placement process. Without a functioning CLAMPER, the pick and place machine would not be able to accurately place components onto circuit boards. It is important to regularly inspect and maintain the CLAMPER to ensure that it is in good working condition.

Regular maintenance of the CLAMPER and other parts of the pick and place machine is essential to prevent breakdowns and ensure optimal performance. This includes cleaning the machine regularly to remove dust and debris that can accumulate over time. Dust and debris can interfere with the machine’s moving parts and cause malfunctions. Regular cleaning can help prevent these issues and prolong the life of the machine.

In addition to cleaning, it is important to regularly inspect the machine for any signs of wear or damage. This includes checking for loose or damaged parts, worn belts, and any other issues that may affect the machine’s performance. If any issues are found during inspection, they should be addressed promptly to prevent further damage to the machine.

Another important aspect of maintaining FUJI pick and place machines is ensuring that they are properly calibrated. Calibration ensures that the machine is placing components accurately and consistently. Improper calibration can result in misaligned components, leading to faulty products. Regular calibration checks should be performed to ensure that the machine is operating within the specified parameters.

Regularly updating the machine’s Software is also important for maintaining optimal performance. Software updates can improve the machine’s efficiency, fix bugs, and add new features. Keeping the machine’s software up to date can help prevent issues and ensure that it is operating at its best.

In addition to regular maintenance, it is important to use high-quality replacement parts when necessary. Using original FUJI parts, such as the FUJI CLAMPER production smt machine AA34T02, can help ensure that the machine continues to operate smoothly and efficiently. Original parts are designed to fit the machine perfectly and are made to the highest standards, ensuring that they will perform reliably.

Proper maintenance of FUJI pick and place machines is essential for ensuring that they continue to operate efficiently and produce high-quality electronic products. By regularly cleaning, inspecting, calibrating, and updating the machine, manufacturers can prevent breakdowns and ensure that their production processes run smoothly. Using high-quality replacement parts, such as the FUJI CLAMPER production smt machine AA34T02, can help prolong the life of the machine and maintain its performance. With proper maintenance, FUJI pick and place machines can continue to be valuable tools in the electronic products manufacturing industry.