Table of Contents

Benefits of Using Green Solder Mask on PCBs

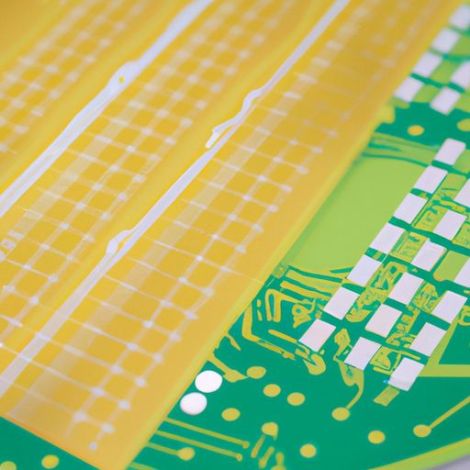

Printed circuit Boards (PCBs) are an essential component in the world of electronics. They provide a platform for electronic components to be connected and communicate with each other. One crucial aspect of PCBs is the solder mask, which is a protective layer that covers the Copper traces on the board. The solder mask helps prevent short circuits and ensures that the components are properly soldered onto the board. While there are various colors of solder mask available, green is the most commonly used color in the industry. In this article, we will explore the benefits of using green solder mask on PCBs.

One of the main advantages of using green solder mask is its high contrast with the copper traces on the board. This high contrast makes it easier for technicians to visually inspect the board for any defects or issues. Green solder mask also provides a clean and professional look to the PCB, which is important for many electronic applications. Additionally, the green color is easy on the eyes and does not cause strain or fatigue during prolonged use.

Another benefit of green solder mask is its excellent thermal resistance. PCBs are often subjected to high temperatures during the soldering process, and the solder mask must be able to withstand these temperatures without degrading. Green solder mask has a high thermal resistance, which ensures that the board remains protected even under extreme conditions. This thermal resistance also helps prevent the solder mask from melting or warping during the soldering process.

Another benefit of green solder mask is its excellent thermal resistance. PCBs are often subjected to high temperatures during the soldering process, and the solder mask must be able to withstand these temperatures without degrading. Green solder mask has a high thermal resistance, which ensures that the board remains protected even under extreme conditions. This thermal resistance also helps prevent the solder mask from melting or warping during the soldering process.

Green solder mask is also known for its excellent electrical insulation properties. The solder mask acts as a barrier between the copper traces on the board, preventing any unwanted electrical connections or short circuits. This insulation property is crucial for ensuring the reliability and performance of the PCB. Green solder mask also helps protect the board from environmental factors such as moisture and dust, which can cause corrosion and damage to the components.

In addition to its functional benefits, green solder mask is also environmentally friendly. The color green is often associated with nature and sustainability, making it a popular choice for eco-conscious manufacturers. Green solder mask is typically made from epoxy resin, which is a non-toxic and recyclable material. This means that PCBs with green solder mask can be safely disposed of without harming the Environment.

When it comes to manufacturing PCBs with green solder mask, it is important to choose a reliable and experienced PCB factory. Universal printed BGA board PCB factory in China offers high-quality PCBs with green solder mask in various configurations, including 8 layer multilayer boards. Their state-of-the-art facilities and advanced technology ensure that the PCBs meet the highest standards of quality and performance.

In conclusion, green solder mask offers a wide range of benefits for PCBs, including high contrast, thermal resistance, electrical insulation, and environmental friendliness. Choosing green solder mask for your PCBs can help improve the reliability, performance, and aesthetics of your electronic devices. With the help of a reputable PCB factory like Universal printed BGA board PCB factory in China, you can ensure that your PCBs are manufactured to the highest standards of quality and precision.

Exploring the Advantages of Universal Printed BGA Boards for PCB Assembly

Printed circuit boards (PCBs) are an essential component in the electronics industry, serving as the foundation for various electronic devices. When it comes to PCB assembly, one crucial consideration is the type of solder mask used. The green solder mask is a popular choice due to its versatility and reliability. In recent years, there has been a growing trend towards using universal printed BGA boards for PCB assembly, particularly in China. These boards offer several advantages over traditional PCBs, making them an attractive option for manufacturers.

One of the key advantages of universal printed BGA boards is their ability to accommodate a higher number of layers. Traditional PCBs are typically limited to a certain number of layers, which can restrict the complexity of the circuit design. With universal printed BGA boards, manufacturers can create PCBs with up to 8 layers, allowing for more intricate and compact designs. This is particularly beneficial for devices with multiple components that need to be connected in a precise and efficient manner.

In addition to their increased layer capacity, universal printed BGA boards also offer improved thermal performance. BGA (Ball Grid Array) technology allows for better heat dissipation, which is essential for electronic devices that generate a significant amount of heat during operation. By using universal printed BGA boards, manufacturers can ensure that their devices remain cool and perform optimally, even under heavy usage.

Furthermore, universal printed BGA boards are more cost-effective compared to traditional PCBs. The ability to create complex designs with fewer layers means that manufacturers can reduce the overall size of the PCB, leading to lower material costs. Additionally, the improved thermal performance of BGA technology can help extend the lifespan of electronic devices, reducing the need for frequent repairs or replacements. This can result in significant cost savings for manufacturers in the long run.

Another advantage of universal printed BGA boards is their compatibility with a wide range of components. BGA technology allows for a higher density of connections, making it easier to integrate various components onto the PCB. This flexibility is particularly useful for devices that require multiple Sensors, processors, and Other Electronic Components to function effectively. By using universal printed BGA boards, manufacturers can streamline the assembly process and reduce the risk of compatibility issues between different components.

Overall, universal printed BGA boards offer a range of benefits for PCB assembly, making them an attractive option for manufacturers looking to improve the performance and reliability of their electronic devices. With their increased layer capacity, improved thermal performance, cost-effectiveness, and compatibility with various components, universal printed BGA boards are a versatile and efficient solution for modern electronics manufacturing. As the demand for more advanced and compact electronic devices continues to grow, universal printed BGA boards are likely to become increasingly popular in the industry. By embracing this technology, manufacturers can stay ahead of the curve and deliver high-quality products that meet the needs of today’s consumers.