Table of Contents

The Process of Manufacturing Women’s Sweaters

Women’s sweaters are a staple in many Wardrobes, providing warmth and style during the colder months. The process of manufacturing women’s sweaters involves several steps to ensure a high-quality product that meets the demands of consumers. From selecting the materials to the final finishing touches, each stage of production plays a crucial role in creating a garment that is both fashionable and functional.

Women’s sweaters are a staple in many Wardrobes, providing warmth and style during the colder months. The process of manufacturing women’s sweaters involves several steps to ensure a high-quality product that meets the demands of consumers. From selecting the materials to the final finishing touches, each stage of production plays a crucial role in creating a garment that is both fashionable and functional.

The first step in manufacturing women’s sweaters is selecting the materials. The type of Yarn used can greatly impact the look and feel of the finished product. Manufacturers must consider factors such as softness, durability, and color when choosing the yarn for their sweaters. Natural fibers like wool and cashmere are popular choices for their warmth and luxurious feel, while synthetic fibers like acrylic and polyester offer durability and easy care.

| men sweater manufacturer | luxurt sweater Producer |

| pullover long Producer | zip pullover sweater Producer |

| sweater jersey Maker | winter sweters mens manufacturer |

| cozy sweater manufacturer | \u00a0neck sweaters Maker |

| luxurt sweater Producer | pull personnalise Producer |

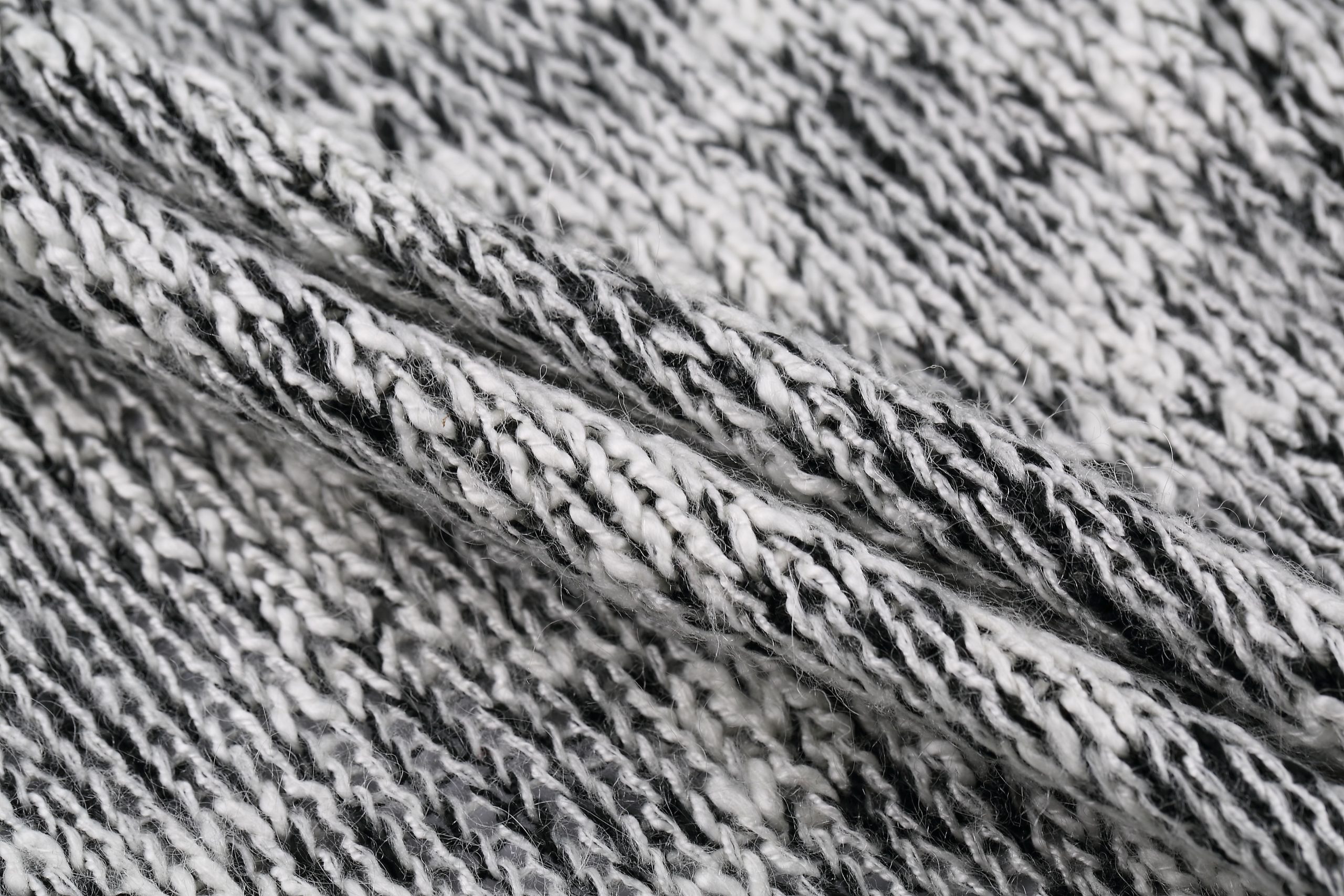

Once the materials have been selected, the next step is knitting the sweater. Knitting Machines are used to create the Fabric panels that will be sewn together to form the sweater. Different knitting techniques can be used to create various textures and patterns, adding visual interest to the garment. Skilled operators monitor the machines to ensure that the fabric is knit to the correct specifications, such as gauge and tension.

After the fabric panels have been knit, they are cut and sewn together to create the final shape of the sweater. This process requires precision and attention to detail to ensure that the seams are strong and the fit is flattering. Quality control measures are put in place to check for any defects or inconsistencies in the stitching. Any issues are addressed before the sweater moves on to the next stage of production.

Once the sweater has been sewn together, it undergoes a finishing process to give it a polished look. This may involve steaming to remove wrinkles, pressing to create crisp edges, and adding any embellishments or trims. The finishing touches can greatly enhance the overall appearance of the sweater, making it more appealing to consumers.

Throughout the manufacturing process, quality control is a top priority. Inspectors carefully examine each sweater to ensure that it meets the company’s standards for fit, finish, and overall quality. Any garments that do not pass inspection are either repaired or discarded to maintain the brand’s reputation for excellence.

| \u00a0women long sweater Maker | men sweaters winter manufacturer |

| \u00a0women sweater vest Maker | sweater mens Maker |

| knitted vest custom Producer | sueter masculino Maker |

| kazak sueter Maker | knitted vest top Producer |

| formal sweater for men Maker | men sweater Producer |

In addition to traditional manufacturing methods, some companies offer bespoke services for women’s sweaters. This allows customers to customize their sweaters with unique colors, patterns, and details to create a one-of-a-kind garment. Bespoke sweaters are made to order, ensuring a perfect fit and personalized design that reflects the customer’s individual style.

In conclusion, the process of manufacturing women’s sweaters is a complex and intricate one that requires skill, attention to detail, and a commitment to quality. From selecting the materials to the final finishing touches, each step plays a crucial role in creating a garment that is both stylish and functional. Whether produced through traditional methods or bespoke services, women’s sweaters continue to be a popular choice for fashion-conscious consumers seeking warmth and style.