Table of Contents

Benefits of Using Zone Control Valve Assembly in HVAC Systems

Zone control valve assembly is an essential component in HVAC systems that allows for precise control over the distribution of heating and cooling throughout a building. By dividing a building into multiple zones, each with its own thermostat and control valve, zone control valve assembly enables more efficient and customizable temperature regulation. This not only improves comfort for occupants but also helps to reduce energy consumption and lower utility costs.

One of the key benefits of using zone control valve assembly in HVAC systems is the ability to tailor heating and cooling to specific areas of a building based on occupancy and usage patterns. For example, in a residential setting, bedrooms can be kept cooler during the day when they are not in use, while living areas can be kept at a comfortable temperature. In a commercial building, zones can be adjusted to accommodate varying Levels of activity throughout the day, ensuring that energy is not wasted on heating or cooling unoccupied spaces.

Another advantage of zone control valve assembly is the ability to address temperature imbalances within a building. By independently controlling the flow of heated or cooled air to different zones, it is possible to correct for areas that are consistently too hot or too cold. This can help to eliminate hot and cold spots, creating a more uniform and comfortable Environment for occupants.

In addition to improving comfort and energy efficiency, zone control valve assembly can also extend the lifespan of HVAC equipment. By reducing the workload on the system and allowing for more precise control over temperature settings, zone control valve assembly can help to prevent unnecessary wear and tear on components. This can result in fewer breakdowns and repairs, as well as a longer overall lifespan for the HVAC system.

Furthermore, zone control valve assembly can offer cost savings for building owners and occupants. By only heating or cooling the areas that are in use, rather than the entire building, energy consumption can be significantly reduced. This can Lead to lower utility bills and a more sustainable approach to heating and cooling. Additionally, the ability to customize temperature settings in different zones can help to prevent overheating or overcooling, further reducing energy waste.

Overall, zone control valve assembly is a valuable tool for optimizing the performance of HVAC systems in both residential and commercial buildings. By providing greater control over temperature distribution, addressing temperature imbalances, extending equipment lifespan, and offering cost savings, zone control valve assembly can help to create a more comfortable, efficient, and sustainable indoor environment. Whether retrofitting an existing HVAC system or designing a new one, incorporating zone control valve assembly is a smart investment that can yield significant benefits for building owners and occupants alike.

Step-by-Step Guide to Installing Zone Control Valve Assembly in a Building

Zone control valve assembly is an essential component in a building’s HVAC system, as it helps regulate the flow of water or steam to different zones within the building. Installing a zone control valve assembly requires careful planning and precise execution to ensure optimal performance and efficiency. In this step-by-step guide, we will walk you through the process of installing a zone control valve assembly in a building.

The first step in installing a zone control valve assembly is to determine the location of the valve assembly. This will depend on the layout of the building and the specific requirements of the HVAC system. It is important to choose a location that allows for easy access to the valve assembly for maintenance and repairs.

Once the location has been determined, the next step is to prepare the area for installation. This may involve removing any existing piping or equipment that may be in the way. It is important to ensure that the area is clean and free of debris before proceeding with the installation.

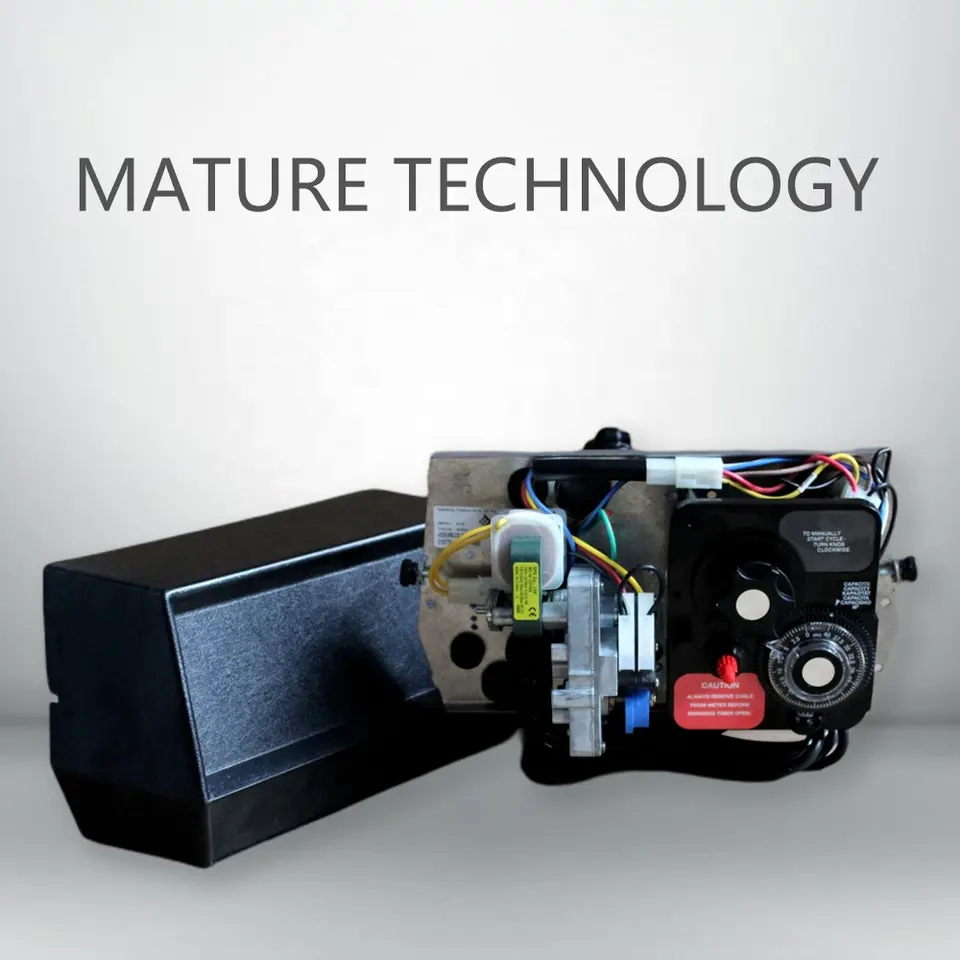

The next step is to assemble the zone control valve assembly. This may involve connecting the valve body to the actuator, as well as attaching any necessary fittings and Connectors. It is important to follow the manufacturer’s instructions carefully to ensure that the assembly is done correctly.

Once the zone control valve assembly has been installed, the next step is to test the system to ensure that it is functioning properly. This may involve opening and closing the Valves to check for proper operation, as well as checking for any leaks or other issues. It is important to address any problems that may arise during testing before proceeding with the final steps of the installation.

| fixed\u00a0 bed GR-1 | ||||

| Model | GR2-1/ GR2-1 LCD | GR4-1/ GR4-1 LCD | GR10-1 Top Loading | GR10-1 Side Loading |

| Output Max | 4T/H | 7T/H | 15T/H | 15T/H |

The final step in installing a zone control valve assembly is to commission the system. This may involve adjusting the settings on the actuator to ensure that the valves are opening and closing as intended. It is important to test the system under normal operating conditions to ensure that it is functioning properly.

In conclusion, installing a zone control valve assembly in a building is a complex process that requires careful planning and precise execution. By following the steps outlined in this guide, you can ensure that your zone control valve assembly is installed correctly and functions efficiently. Remember to consult with a professional HVAC technician if you encounter any difficulties during the installation process.