Table of Contents

Advantages of Custom Injection Molding Service for ABS Materials

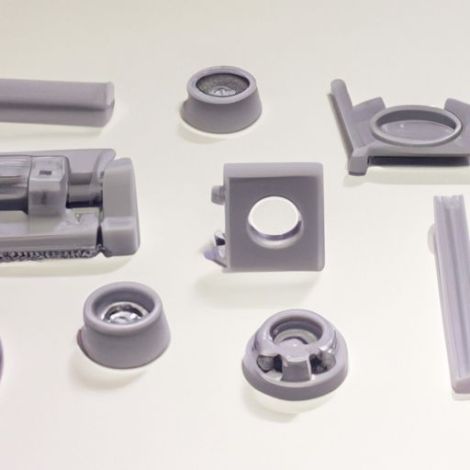

Custom injection molding service for ABS materials offers a wide range of advantages for businesses looking to create high-quality plastic parts for various projects. ABS, or acrylonitrile butadiene styrene, is a versatile thermoplastic Polymer that is commonly used in injection molding due to its excellent mechanical properties, impact resistance, and heat resistance. By utilizing a custom injection molding service for ABS materials, businesses can benefit from precise and efficient production processes that result in durable and cost-effective plastic parts.

One of the key advantages of custom injection molding service for ABS materials is the ability to create complex and intricate designs with high precision. Injection molding allows for the production of parts with tight tolerances and intricate geometries that would be difficult or impossible to achieve with other manufacturing methods. This level of precision is essential for industries such as automotive, electronics, and consumer goods, where the quality and functionality of plastic parts are crucial.

In addition to precision, custom injection molding service for ABS materials offers fast and efficient production processes that can help businesses meet tight deadlines and production schedules. Injection molding is a highly automated process that can produce large quantities of parts in a relatively short amount of time. This efficiency not only reduces production costs but also allows businesses to quickly respond to changes in demand or design requirements.

Furthermore, custom injection molding service for ABS materials provides businesses with the flexibility to create parts in a wide range of sizes and shapes. Whether it’s small, intricate components or large, complex assemblies, injection molding can accommodate a variety of part sizes and configurations. This versatility is particularly beneficial for businesses that require a diverse range of plastic parts for different applications.

Another advantage of custom injection molding service for ABS materials is the ability to achieve consistent and repeatable results. Injection molding processes are highly controlled and monitored, ensuring that each part produced meets the required specifications and quality standards. This level of consistency is essential for industries where uniformity and reliability are paramount, such as medical devices, aerospace, and Telecommunications.

Another advantage of custom injection molding service for ABS materials is the ability to achieve consistent and repeatable results. Injection molding processes are highly controlled and monitored, ensuring that each part produced meets the required specifications and quality standards. This level of consistency is essential for industries where uniformity and reliability are paramount, such as medical devices, aerospace, and Telecommunications.

Moreover, custom injection molding service for ABS materials offers cost-effective solutions for businesses looking to produce plastic parts in large quantities. Injection molding is a highly efficient process that minimizes material waste and reduces labor costs compared to other manufacturing methods. This cost-effectiveness allows businesses to scale up production without significantly increasing production costs, making it an attractive option for businesses looking to maximize their return on investment.

In conclusion, custom injection molding service for ABS materials offers a wide range of advantages for businesses looking to produce high-quality plastic parts for various projects. From precision and efficiency to flexibility and cost-effectiveness, injection molding provides businesses with the tools they need to create durable and reliable plastic parts that meet their specific requirements. By partnering with a reputable custom injection molding service provider, businesses can leverage the benefits of ABS materials and injection molding processes to achieve their production goals and stay ahead of the competition.

How to Choose the Right Plastic Part Project for Injection Molding Service

Injection molding is a popular manufacturing process used to produce a wide range of plastic parts. From automotive components to medical devices, injection molding offers a cost-effective and efficient way to mass-produce plastic parts with high precision and consistency. When it comes to choosing the right plastic part project for injection molding service, there are several factors to consider to ensure a successful outcome.

One of the first things to consider when selecting a plastic part project for injection molding service is the material. Different plastics have different properties, such as strength, flexibility, and heat resistance. It is important to choose a material that is suitable for the intended application of the part. ABS (Acrylonitrile Butadiene Styrene) is a commonly used material for injection molding due to its high impact resistance and good overall mechanical properties. However, there are many other materials available, so it is important to consult with a knowledgeable injection molding service provider to determine the best material for your specific project.

Another important factor to consider when choosing a plastic part project for injection molding service is the design of the part. The design of the part will impact the mold design, production process, and overall cost of the project. It is important to work closely with an experienced design engineer to ensure that the part is designed for manufacturability. This includes considerations such as draft angles, wall thickness, and undercuts. A well-designed part will not only be easier to mold but will also result in a higher quality finished product.

In addition to material selection and part design, it is important to consider the volume of parts needed for the project. Injection molding is a cost-effective process for high-volume production runs, as the initial tooling costs can be spread out over a large number of parts. However, if only a small number of parts are needed, it may be more cost-effective to consider alternative manufacturing processes such as 3D printing or CNC Machining. It is important to work with an injection molding service provider who can help you determine the most cost-effective production method for your specific project.

When choosing a plastic part project for injection molding service, it is also important to consider any secondary operations that may be required. This could include processes such as assembly, painting, or packaging. It is important to work with an injection molding service provider who can offer a full range of secondary operations to ensure that your project is completed to your exact specifications.

In conclusion, choosing the right plastic part project for injection molding service requires careful consideration of material selection, part design, production volume, and secondary operations. By working closely with an experienced injection molding service provider, you can ensure that your project is completed on time and within budget. Whether you are looking to produce a small batch of custom parts or a large production run, injection molding offers a cost-effective and efficient solution for your plastic part project.